Circor Enhances Allweiler Emtec-C and Creates one Machine Tool Coolant Pump for Every Pressure Demand

Plant engineers can now choose one Circor coolant pump to handle pump outlet pressure needs from 0 - 100 bar. The Allweiler Emtec-C three-screw coolant pump introduced last year handles even higher pressure applications than before, increases overall speed and efficiency, and offers manufacturers one simplified pump suitable for keeping abrasive machine chips, particles and heat away from cutting surfaces in machine tool coolant service.

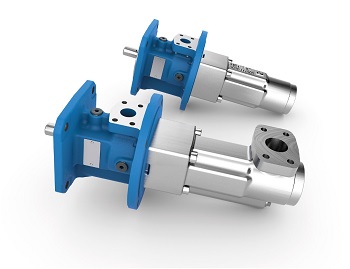

The enhanced Emtec-C from Allweiler with up to 100 bar. (Image: Allweiler

By engineering one pump for any pressure condition, we re covering the whole range of customer requirements with one brand and model," said Daniel Stirpe, Circor Vice President and General Manager, Industrial Pumps, EMEA, India & Asia. "We re eliminating the unnecessary complexity of installing and maintaining multiple pumps, while continuing to provide the extreme precision and performance-focused fluid handling technology that the industry has come to expect of Allweiler."

Used in high-pressure machine tool coolant service for metalworking, transfer lines, grinding and deep drilling machine applications, Emtec-C users can customize their solution from a variety of sizes and spindle pitch angles. The pump accommodates tank-top, submerged and horizontal configurations.

The enhanced Emtec-C continues to offer a lightweight, easy-maintenance three-screw pump solution that will go the distance with good, limited or poor lubricating liquids as well as abrasive fluids. Its patented reversed hanging idler and integrated thrust compensation system, seal options, transparent backflow pipe and extra-long piston are all thoughtfully designed to improve durability and performance while minimizing flow loss.

Customers can order the enhanced Emtec-C 100 bar option in screw pitch angles of size 20 now, and size 40 beginning in August.

Source: ALLWEILER GmbH