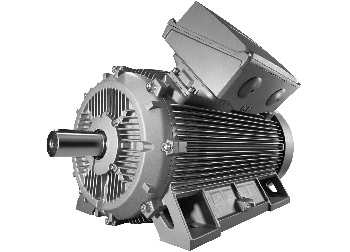

High Performance Along the Entire Value Chain with Simotics SD Pro from Siemens

Simotics SD Pro completes the next generation of low-voltage Simotics SD motors from Siemens. The new variant is equally suited for mains-fed operation or for use with a converter for voltages up to 690 volts (V). There is generally no need to use special filters at the converter output.

The new Simotics SD Pro variant completes the series of next-generation low-voltage motors from Siemens and is predestined for flexible application around the globe. (Image: Siemens)

The Simotics SD Pro motors reliably fulfill the requirements for compliance with efficiency class IE3, irrespective of whether they are operated at 50 or 60 hertz (Hz). Used in conjunction with a comprehensive range of industry-specific and country-specific certificates, they can be used in all the world s most important regions and markets, and also in wide-ranging different plant configurations. The Simotics SD Pro offers the bonus of multi-voltage capability, making it ideal for series production by OEMs. The motors can be stably operated with all power supplies in common use around the world, and fulfill the requirements for compliance with the respective efficiency class at all operating points. This motor variant operates with the utmost reliability and efficiency under even the toughest enviromental conditions such as those prevailing in the oil and gas industry. Typical applications for the low-voltage motors include pumps, compressors, fans, cranes and hoists, conveyors, chippers, coilers, grinders, shears and rolling stands.

The Simotics SD Pro variant is currently available in shaft heights 315 to 450, and in the 2 and 4-pole version covers a rated power output range of 250 to 980 kilowatts (kW). Further 6 to 8-pole versions are also available in various types of construction. The compact design and further reduced cover size make these motors suitable for greenfield and retrofit projects. Due to the flexible terminal concept there will be up to 40 possibilities of terminal box positioning to be adjusted individually to local circumstances, significantly simplifying the installation process.

With this new generation of motors, Siemens has focused on providing major benefits for customers and enabling high performance along the entire value chain. Short delivery periods, extended scope for configuration and support by electronic configuration and engineering tools all help to improve planning flexibility while reducing the costs and effort expended on complex configuration and ordering processes.

All the variants of the new Simotics SD next generation motor series – Simotics SD, Simotics SD Add and Simotics SD Pro – are designed to help users optimize their processes across the entire life cycle from the design stage through to servicing, smoothing the path towards the digital future. Engineering processes are speeded up by using a virtual copy of the motor, its digital twin, which is continuously updated by Siemens. Using 2D drawings and 3D models, machines and plants can be simulated to enable more rapid design and development. This significantly reduces the time to market, which can be decisive in today s toughly competitive marketplace.

Using the machine-readable data matrix code attached to the motor in conjunction with the Simotics Digital Data App, users are able to access electrical and mechanical data, operating instructions and manuals at any time for the 315 and 355 shaft height motors.

Source: Siemens Aktiengesellschaft