Bahrain Petroleum Company Refinery Uses GE’s Mobile Water Solutions

According to the World Resources Institute, Bahrain is one of the most water-stressed countries in the world and will continue to be through at least 2040.

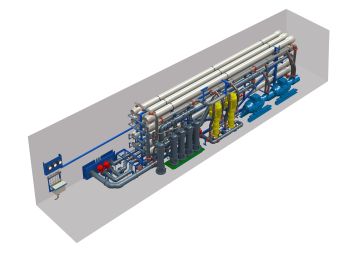

Bapco is using GEs mobile SeaTech 84 containerized reverse osmosis systems to supply high quality source water for the refinery (Image: GE)

To save as much water as possible in the production of oil and eliminate the need to deliver water via tanker truck, the Bahrain Petroleum Company B.S.C. (Bapco) is using GE s advanced mobile water technology to convert seawater into usable, highly pure source water at the Awali refinery.

Bapco refines more than 260,000 barrels per day of crude oil. Its oil is exported throughout the Middle East, India, the Far East, Southeast Asia and Africa. Using GE Water & Process Technologies’ mobile water technology gives Bapco a cost-effective solution for on-site desalination.

“GE’s mobile water solutions enabled Bapco to convert seawater into high-purity boiler feedwater for refinery use," said Yousif Ahmed, acting manager, power and utilities, Bapco. “Availing mobile water solutions ensure a continual water supply instead of relying on tank truck deliveries.”

Previously, the limited in-house distillate water production from the desalination units prompted Bapco to import water using tank trucks to fill up the shortage. This mode of delivery would cause gridlock on refinery roads, and there were associated risks involved in having unusual numbers of tankers inside the refinery operating area.

For the project, GE Water & Process Technologies provided Bapco a turnkey operations and maintenance solution with a total of 13 mobile water units including six mobile seawater multimedia filter containers, five mobile seawater reverse osmosis containers, two mobile brackish water reverse osmosis containers and four diesel-operated electrical generators. GE also supplied all mobile pumping skids, tanks and interconnecting piping and cabling. The mobile water fleet started its operation in May 2017 and will continue to produce Bapco’s desalinated water requirements for one year.

“For the Bapco refinery, GE’s mobile water technology produces 136 m3/h of water, which meets the refinery’s high-quality standards," said Kevin Cassidy, global leader, engineered systems—GE Water & Process Technologies. “Our mobile solutions allow Bapco to desalinate the water on-site and immediately use it for oil refining.”

Source: General Electric Company