Lip Sealings Safe Against Dry Running Prove Themselves for Fruit Juice Concentrates

The transport of viscous sugar-containing fruit juice concentrate makes great demands on the sealing technology. For such applications Jung Process Systems equips their Hyghspin screw spindle pumps with special lip ring sealings executed as shaft sealings.

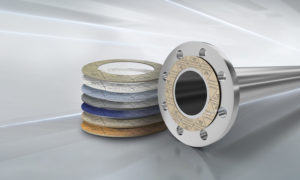

Shaft sealings with lip sealing ring prove themselves in numerous Hyghspin screw spindle pumps for fruit juice concentrates (Image: Jung Process Systems)

The lip sealings are safe against dry-running even without separate rinsing systems. Moreover damages are avoided which might arise during start-up by sticky sealing surfaces. By elimination of these potential weak points in the sealing system the pump availability is considerably increased and costs for purchase, maintenance and spare parts are noticeably reduced.

Mainly for fruit juice concentrates with high sugar contents single-acting standard mechanical seals cannot be considered. At a standstill of the pumps the slide surfaces can easily get sticky, thus breaking at restarting. Single-acting mechanical seals with reduced sealing surfaces offer, however, effective protection, but they are not safe against dry-running. As a consequence rinsed double-acting mechanical seals have been established to avoid damages of the slide surfaces due to insufficient lubrication and overheating. For this reason the danger of an undesired sealing failure has been eliminated, however, no solution was found for an attractive cost situation for a shaft sealing safe against dry-running. Moreover an external rinsing system will be necessary. In addition difficulties are arising the moment fruit juice concentrates will be transported in frozen condition. At temperatures below 0 °C no rinsing water can be used because of ice formation. Essential is the application of a recirculation system together with alternative rinsing media such as thin food grade oils. This causes investment and maintenance expenses. A recirculation system requires a continuous control because undesired germs can result and grow. In case of using a rinsing medium on base of alcohol in order to reduce freezing temperature it has to be observed that rinsing medium will get lost by evaporation of alcohol so that it has to be refilled regularly.

Lip sealings are safe against dry-running

For elimination of these weak points in the sealing system Jung Process Systems equips the Hyghspin screw spindle pumps with lip sealings for fruit juice concentrates. The sealing of the pump shaft is effected by means of a self-lubricating PTFE lip sealing. An external rinsing system is not necessary so that the lip sealings are specially advantageous for mobile pumps.

The ready-to-install lip sealing system is simply designed, easy to clean and economically priced compared with single-acting and double-acting mechanical seals. In case of wear and tear only the sealing lips have to be exchanged. Customers’ feedback is very positive and lifetime of the sealings is excellent.

Source: Jung Process Systems GmbH