Portuguese Olive Mill Quadruples Production Capacity with New Alfa Laval Technology

A forward-thinking step in the Alto Alentejo region helps preserve generations of farming heritage (Image source: Alfa Laval Corporate AB)

As the last remaining mill in Montemor-o-Novo, the cooperative group recognized the urgent need to evolve in order to continue serving a growing community of farmers seeking to process olives from their groves. “We either modernized the process or lost competitiveness,” states José Ferreira, the retired operator who dedicated over two decades to the olive oil mill.

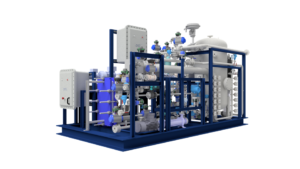

Alfa Laval, a trusted technology partner for decades, played a key role in the transformation. “Caminhos do Futuro has always had a vision focused on innovation, and Alfa Laval has supported us every step of the way,” says Nelson Fialho, current general manager. “The decision to invest in a brand-new first-extraction line followed months of careful evaluation and collaboration with their experts to identify the optimal solution for our needs.”

The mill already had an Alfa Laval olive oil decanter in operation since 1998, along with two high speed separators acquired in 1989 when the first line was installed—all of which remain mechanically efficient today. This reliability reinforced their decision to follow Alfa Laval’s recommendation to repurpose the original line for secondary processing. Since 2024, the old decanter has been used to process pomace, making use of previously discarded material.

Olive oil innovation towards nourishing a growing global population

With harvest seasons getting shorter due to changing climate conditions, and global demand for healthy, nutritious foods on the rise, Alfa Laval’s new 2-phase decanter centrifuges are being hailed as a significant advancement for small-, medium-, and large-sized mills. Built on the proven Sigma design, the equipment offers improved oil extraction and consistent performance with a simplified, user-friendly interface.

The installed model at Caminhos do Futuro features Sigma’s latest conveyor design, a key innovation that boosts extraction efficiency in every production cycle. “The new conveyor, being longer, increases yield by extending the product flow distance inside the unit, while the patented Active Baffle Disc ensures uninterrupted performance, even under varying feed or process conditions,” explains Rafael Ayuso, olive oil expert at Alfa Laval. “Its simplified setup also reduces downtime and minimizes the need for manual adjustments.”

With peak harvest periods becoming more intense and shorter, the latest Sigma series decanters are manufactured using high-grade materials and protective components intended to withstand high mechanical wear, extend machinery lifespan and maximize performance.

Caminhos do Futuro sees such innovation as essential to meeting the needs of the next generation of olive growers.

Source: ALFA LAVAL Corporate AB