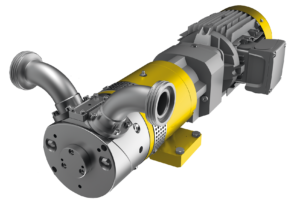

A New Modular Canister Pump Tube that Improves Health and Safety in Industry and Trade

The new canister pumping stations are compatible with a wide range of canister sizes and media. (Image source: Lutz Pumpen GmbH)

A clip-on battery-powered motor enables users to fit several canisters with a pump tube and switch flexibly between them to pump liquids safely and automatically.

Many companies in industry and trade use hand pumps to transfer liquids from canisters – for example, to pump hydraulic oils for machine maintenance or cleaning agents for systems deployed in the food industry. “These pumps are often inefficient and not ergonomic to use, with workers forced to get down on their hands and knees to fill the liquid into intermediate vessels”, explains Andreas Rössler, sales manager at Lutz Pumpen GmbH. “Hand pumps are also associated with risks: liquids can splash or spill, resulting in a danger of slipping or skin contact with harmful substances”. They can also lead to contamination due to carryover between tanks. “Seeking to improve health and safety, we worked to develop a modular pump tube that is one of very few available on the market designed specifically for use in canisters. Used in conjunction with the clip-on motor, users can pump between multiple containers safely and automatically.”

A canister pump tube compatible with a wide range of canister sizes and media

The new pump tubes fit the most common canister sizes. Available in lengths of 400 mm, 500 mm and 700 mm, they are fitted with S60 and S70 threads, widely used in tank technology and for chemicals. With a polyethylene (PE) pump tube and polyvinyl chloride (PVC) hoses and fittings, our pump tube is durable and chemically-resistant. The shaft is made of stainless steel, which offers high mechanical strength and resistance to corrosion. “This combination of materials enables the pumping of a wide range of media, including low-viscosity mineral oils, cooling lubricants, disinfectants, diesel, flame retardants, fungicides and insecticides, as well as various cleaning agents and sanitising products”, says Rössler. The robust design of the pump tubes increases resistance to abrasion and external influences, extends their service life and ensures reliability in industrial applications.

Empty a 200-litre canister 12 times on a single battery charge

Once the pump tubes have been inserted into the canisters, users can attach the B2 battery-powered motor from Lutz Pumpen using a quick-release fastener and start pumping immediately. The 260 watt brushless DC motor reaches a maximum speed of 12,000 revolutions per minute and enables a delivery rate of up to 6 litres of liquid with a maximum viscosity of 400 mPas. A single charge of the replaceable battery is enough to empty a 200-litre canister twelve times in around 35 minutes.

Source: Lutz Pumpen GmbH