Amarinth Delivers Vertical In-Line Centrifugal Pumps to the Hertfordshire Oil Storage Terminal

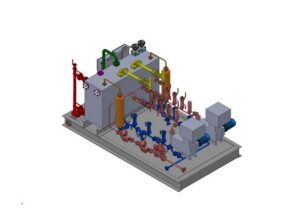

Amarinth ISO 5199 vertical in-line centrifugal pump ready for packing before transport to the Hertfordshire Oil Storage Terminal (Image source: Amarinth Limited)

The Hertfordshire Oil Storage Terminal (also known as the Buncefield oil depot) is located on the edge of Hemel Hempstead to the north of London, United Kingdom, and operates bulk storage and supply of fuel. Amarinth were approached, as an approved supplier, for two ISO 5199 vertical in-line centrifugal pumps for loading duties at the depot. The pumps were specified to operate safely in an explosive atmosphere, certified for ATEX Zone 1. The order also called for the pumps to be designed so that variable speed drives could be added later as their operational use was planned to change.

Eight weeks after the initial order however, Amarinth were again approached by the client for a further two of the same vertical in-line centrifugal pumps but on the same delivery schedule as the original order.

Amarinth was able to replan the project, drawing on its renown agility to meet the original deadline for all four of the pumps. Leveraging its close relationship with the foundry in the UK, the castings for the four pumps were completed together, rather than in pairs, ensuring assembly and testing could be completed on schedule, achieving the original delivery dates requested. The pumps were commissioned by Amarinth’s site services team in 2023 at the Hertfordshire Oil Storage Terminal.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “We have supplied centrifugal pumps for this super-major client for numerous projects over many years, often on short lead times, and are pleased that we could once again fulfil this latest order on-time, despite the additional pumps required. We have fostered close working relationships with our supply chain, who have supported us in being agile and responsive when faced with tight deadlines and order changes, particularly through the difficult times during and immediately following the global Covid-19 pandemic.”

Source: Amarinth Ltd.