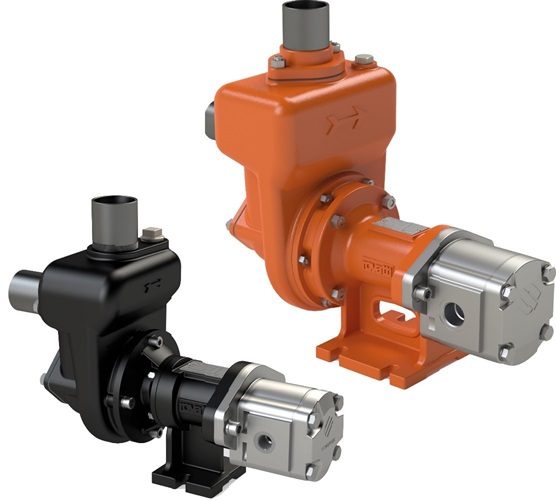

Rovatti Presents New Range of Self-Priming Pumps for Hydraulic Motors

Rovatti Presents New Range of Self-Priming Pumps for Hydraulic Motors (Image source: Rovatti Pompe S.p.A.)

The new HA series cast-iron self-priming pumps is composed of three models with 2’’ and 3’’ inlet/outlet which achieve a maximum flow rate of 72 m3/h and maximum head of 36 m.

The HL and HX series centrifugal pumps achieve maximum flow rate of 140 m3/h and maximum head of 70 m.

All of the H series are easily coupled with hydraulic motors via SAE B flange and 13T-16/32 DP splined shaft, meaning that no flexible coupling is required.

The pumps are compact and feature versatile installation because the position of the pump is not bonded to a PTO or drive shaft. The H series pumps are suitable both for fixed ground installations and vehicle installations.

The performance of the pumps is easily customised as it depends on the supply of the hydraulic fluid to the motor, which can be quickly regulated. The H series pumps can therefore be used at different speeds up to 3000 min-1 and thus perform different services for the same installation, or be used for different applications.

Cleaning and maintenance operations are simplified because the pump and motor are easy to separate.

The H series stands out as a technical benchmark for pumps for excavation drainage, washing systems, spraying systems, fluid transfer, and dust abatement in a range of industrial and agricultural sectors.

Source: Rovatti Pompe S.p.A.