KSB Highlights New High-Efficiency Mixers

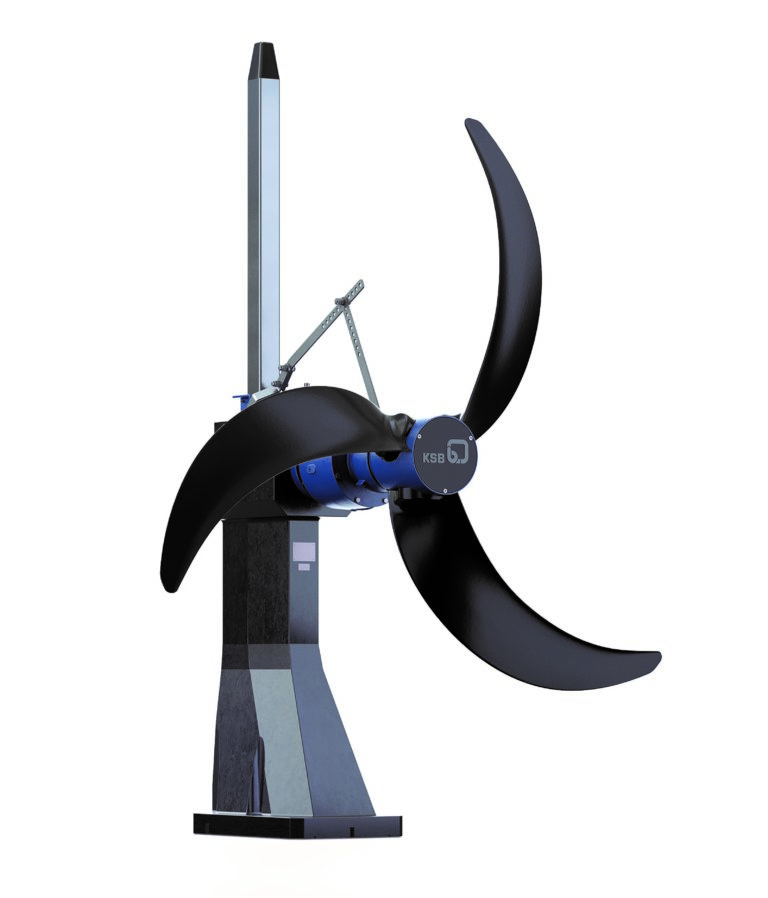

The new high-efficiency AmaProp mixers for use in waste water treatment (Image source: KSB SE & Co. KGaA)

The electric drives are either IE5 Ultra Premium Efficiency synchronous reluctance motors or IE3 Premium Efficiency asynchronous motors with ratings from 0.85 to 20.0 kW. Unlike conventional synchronous motors, the IE5 synchronous reluctance motors are made without any magnetic materials such as rare earths that are categorised as critical raw materials since their extraction causes severe environmental impacts in their countries of origin.

The necessary shaft sealing is performed by two bi-directional mechanical seals in tandem arrangement with a liquid reservoir. The latter is filled with environmentally friendly, ecologically acceptable white oil. An oil sensor fitted at the mating ring of the mechanical seal triggers an alarm if any damage occurs to the mechanical seals.

As standard, the motors are equipped with maintenance-free bearings and temperature sensors to protect the winding against overheating. They are also fitted with leakage sensors. Users can order additional sensor packages to monitor the bearing temperature or vibrations, for example.

The glass fibre reinforced two-blade or three-blade epoxy resin propellers are as lightweight as they are break-proof. The surface is provided with a special protective gel coating, effectively preventing corrosion and abrasion. Their contour has been developed using computational fluid dynamics simulation. Propeller diameters range from 800 to 2600 mm and cover all fields of application.

Low propeller speeds from 24 to 208 rotations per minute allow optimum adjustment of the mixers to their application. These low speeds are achieved by frequency inverters and helical spur gears with two or three stages. The gears run quietly and are designed for 100,000 operating hours.

Given their robust design, AmaProp mixers have got main maintenance intervals of 16,000 hours or three years. The cable entries are resin-sealed and absolutely watertight. Stable positioning in the treatment tank is taken care of the by the AmaRoc mixer stands that are made of particularly solid and resistant cast polymer concrete.

Source: KSB SE & Co. KGaA