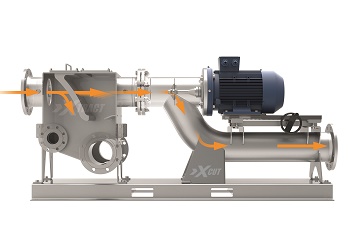

Wangen X-Unit – The Modular System for Debris Removal and Cutting

The Wangen X-Unit offers a wide range of applications for when foreign bodies and impurities in the conveyed media must be separated out and cutted. Versatile for a wide range of applications: E.g. in biogas plants, biowaste utilisation, stable application in agricultural technology, liquid manure technology vehicle construction and municipal waste water treatment plant.

Increased process safety:

Increased process safety:

The complete system for debris removal and cutting protects pumps and systems against stones, wood, metal parts or other foreign bodies. Knotted plaits and similar blockades in the system are avoided and associated downtimes reduced considerably.

Clear advantages, thanks to modular structure:

The X-Tract and X-Unit components are available separately and also as an optimally co-ordinated X-Unit. A significant advantage is also the fact that, during maintenance of the X-Cut module (e.g. with the replacement of the measuring units), the X-Tract foreign body separator can continue to be used.

Wangen X-Tract module for debris removal

- Process-optimised adaptation to the pumped media through a simple change of the sceen geometry

- Easy removal of the foreign bodies through large openings

- Rugged implementation

- Continuous cleaning as a result of the geometry of the rake

- Large openings for easy extraction of the foreign bodies

- Maximum capacity: 1,250 m3//h / 347 l/sec

Gravity causes conveyed media with a higher density than water to sink down.

The media is then routed by the screen and the container geometry to the removal opening. Therefore no movable component parts are necessary for the separation of such foreign bodies. The geometry of the screen guarantees continuous cleaning through the inflowing pumped medium.

Wangen X-Cut the cutting module as an extension to the X-Tract

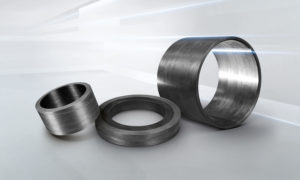

- Rugged implementation

- Compact and space-efficient construction design

- Cutting tool from 4 hardened, tool-steel blades

- Long service lives due to high-quality materials and turning blades

- Low life-cycle costs, thanks to low wear costs of the cutting unit

- Simple and rapid replacement of the cutting knives by means of central tensioning screw

- Powerful motor guarantees reliable cutting

- Maximum capacity: 1,250 m3/h / 347 l/sec

´

The comminution unit can be optimally adapted to the conveyed medium with a simple modification.

The modular X-Unit system is available from January 2018.

Picture: Illustration of the flow directions of media through the X-Unit (Image: Pumpenfabrik Wangen)

Source: Pumpenfabrik Wangen GmbH