Vogelsang Launches RedUnit XRL260 Industrial Grinder for High Throughput Quantities

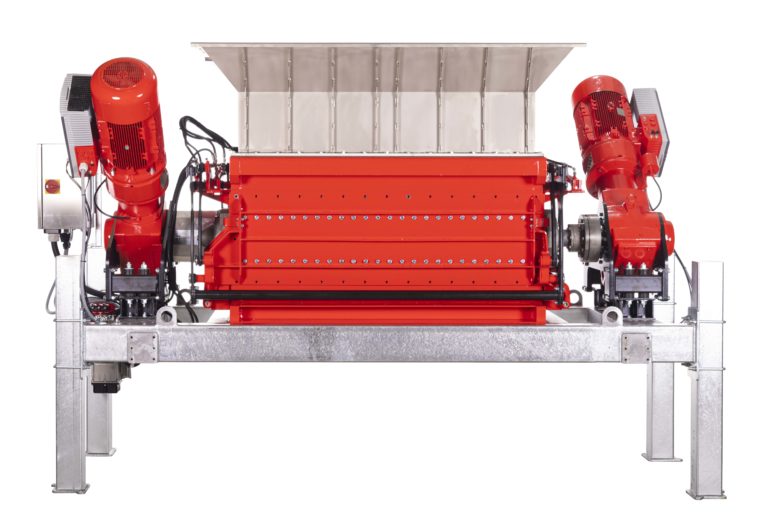

The RedUnit XRL260 industrial shredder ensures high throughput rates. (Image source: Vogelsang GmbH & Co. KG)

Two geared motors, each with up to 37 kW, ensure high throughput performance of up to 100 m3/h. Lateral service hatches – part of the new Vogelsang service concept – offer direct, simplified access to the rotors.In addition, it is now easier to remove foreign bodies, since the fill area of the machine no longer requires elaborate clearing.

“Our customers in the meat-, food and recycling industries need a high performance grinder for reliable, flexible processing of even large quantities of material. For example, during the current widespread bird flu in Germany, many culled animals had to be destroyed quickly; the RedUnit XRL260 proved to be a real problem solver here,” says Harald Vogelsang, CEO of Vogelsang GmbH & Co. KG. Furthermore: “By prioritizing factors like throughput, cleaning, maintenance and downtime during development, we make it possible for companies to even further enhance their process efficiency with our new industrial grinder.”

Powerful and service-friendly

The RedUnit's core features two ripper rotors, which are each driven by their own motor. Users can individually guide the rotation direction and speed of the respective rotors. If materials block the rotors, they reverse and the foreign bodies can be removed through the lateral hatches. Moreover, the hatches offer direct, easy access to the rotors. As a result, the latter are easy to reach with the associated installation tools during maintenance or replacement. One person can demount the ripper rotors independently. Removing the feed and discharge systems is unnecessary. Vogelsang thus has boosted the system's availability and cut the downtime of the machine to a minimum. Support feet, a filling shaft or a system solution for easy integration with existing installations are also available as additional options.

The grinder is available in the sizes XRL260-800, XRL260-1200 and XRL260-1600 with various blade sizes. All models feature continuous height adjustment. The RedUnit XRL260-1600 is the biggest grinder in the series with a floor area of 1.80 x 3.60 meters. Customers can borrow this model to test it in their business or rent it on a long-term basis.

Source: Vogelsang GmbH & Co. KG