ViscoTec Launches New Pump for Liquids and Pastes

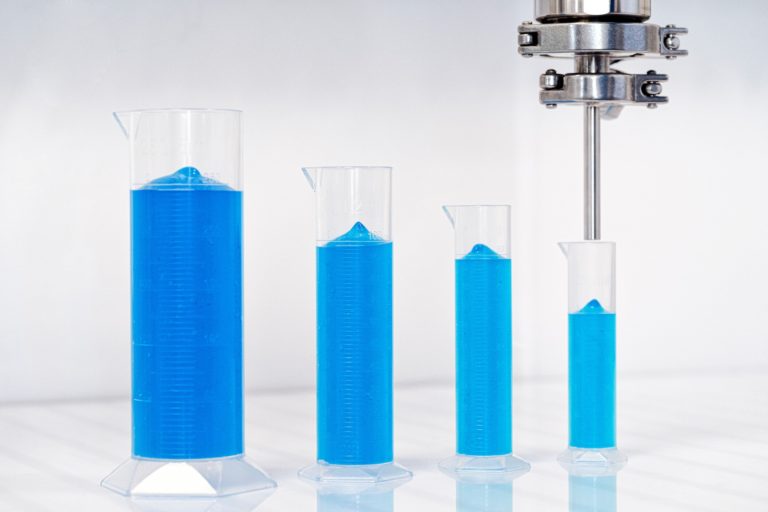

vipura-PUMP 10T - compact and universally suitable. (Image source: ViscoTec Pumpen- u. Dosiertechnik GmbH)

The compact design of the vipura-PUMP 10T makes it easy to integrate the dosing and filling pump into complete systems: The installation space length has been reduced by over 25 percent compared to pumps with the same dosing capacity; with a weight reduction of over 60 percent. At the same time, the dosing volume per revolution has been increased. The special dosing geometry ensures precise dosing results and short cycle times and works non-destructively, even with lumpy materials up to 20 mm in diameter. The dosing volumes can be flexibly adjusted – from 20 to 200 ml or even much higher, depending on the cycle rate. These quantities can be precisely dosed and filled, depending on the application, and matching the specific requirements.

Easy handling of the vipura-PUMP 10T

Due to its compact size and simple assembly/disassembly options, transportation of the vipura-PUMP 10T can be carried out by one person alone if required. Cleaning is simple and quick via a CIP connection.

The vipura-PUMP 10T is suitable for dosing and filling various materials: For food and pharmaceuticals, as well as household products and cosmetics. Common applications are, for example, tubular bag filling of chunky sauces or marinades, and of pet food or shower gel, detergents, toothpaste, creams, etc.

The benefits:

- Product change is made possible without disassembly

- One size fits all: For different dosing volumes

- Compact design + hygienic design in stainless steel

- Short cycle times

- Non-destructive dosing even of lumpy materials

- Transportation and cleaning can be done by 1 person

- Easy integration into existing systems