Tuborg Fredericia Brewery Chooses APV Pumps

Following a review of existing process equipment the Tuborg Fredericia Brewery decided to install a number of self priming pumps that would work hygienically with both a CIP liquid and with beer.

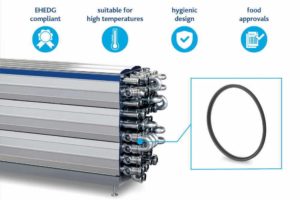

The specification also required that the pumps be EHEDG certified. Following a review of potential products, Tuborg Fredericia Brewery chose the Ws+ 30/30 pumps manufactured by APV. These efficient and reliable pumps will be used to reduce the time taken for the beer to be pumped away from the company’s waste beer tanks.

When the CIP system was changed in 2003, it became apparent that new and improved pumps were needed to resolve priming problems being experienced at the time. Knud E. Hansen, APV’s sales representative, recommended four Ws+ 30/30 pumps for the waste beer tanks. "Our Ws+ 30/30 pumps are ideal for this particular application because of the unique self-priming abilities and because they are hygienic for use with both the CIP liquid and waste beer. We have already successfully installed a number of W+ pumps at the Tuborg Fredericia Brewery and because the main spare parts are identical, parts can be supplied direct from stock – minimising overall costs".

Bent Pallesen, control technician at the Tuborg Fredericia Brewery, is completely satisfied with the four Ws+ pumps. "We chose APV ultimately due to the pumps’ suitability for our application, in addition to the highly professional service provided by APV and, in particular, APV’s project manager, Aage Petersen."

The Tuborg Fredericia Brewery was built in 1979 and, at the time, was one of the most modern breweries in the world with a capacity of approximately 1 million hectolitres per year. Today, some 25 years on, the yearly capacity has increased to approximately 3 million hectolitres that corresponds to approximately 900 million bottles. On average, the brewery produces 35 different types of beer in more than 200 different types of packaging.

Source: SPX FLOW, Inc.