The Last Frontier: How Pumps Support Research Stations and Renewable Energy on Antarctica

As more and more research stations pop up across Antarctica, the need for pumps and pumping solutions is greater than ever.

In addition to the operation of nearly 100 research stations throughout the year, many countries are also exploring the use of renewable energy on Antarctica. Additionally, each research station needs to address fuel and water needs, as well as delivery of chemicals and fluids needed for research purposes.

All of these tasks necessitate the use of pumps for a wide variety of purposes, including:

- Drinking water and wastewater management

- Tanker off-loading

- Fuel storage and use

- Oil and fuel spill containment

- Wind turbine operation

But let’s start with the basics, namely the 5,000 people on Antarctica during the summer months, and more than 1,000 all year long. Which begs the question – where does all their waste go?

According to National Geographic, it goes into the environment. In an article that looks at pollution in Antarctica, it was discovered that the U.S. McMurdo Station, located on the Ross Ice Shelf on the southern end of the continent, was releasing toxins into the McMurdo Sound.

More specifically, the wastewater from the base was found to contain sewage, toxins, organic and inorganic matter, pathogens, and even medications into the water. The worst of these was a toxic flame retardant known as hexabromocyclododecane, or HBCD. As shocking as this is, what’s even more concerning is that ecotoxicologists found that the levels of HBCD in the environment around the research bases equals those found in the rivers of major cities in the U.S.

Wastewater treatment is a critical component of any community, even one as small as a research base. With most treatment plants, contaminants are removed from the water through a variety of processes to separate “sludge” from the resultant reclaimed water. And these processes need pumps.

In fact, pumps are used at virtually every step of the wastewater treatment process, from unloading chemicals from tank trucks to bulk storage and from bulk storage to day tanks to emptying batch treatment tanks. Pumps are also needed to disinfect treated wastewater and dechlorinate wastewater before discharge. They also support the flow of regeneration chemicals for ion exchange tanks.

Wastewater doesn’t need to be a liability. With the right pumps in place, you can have your research and your clean environment too.

Which leads us to the renewable energy and green efforts currently underfoot in Antarctica.

As of 2022, the predominant sources of electricity and heat on Antarctica were from fossil fuels. While these sources are efficient and consistent, they have a negative environmental impact. Given this, research stations on the continent have been exploring the use of renewable energy sources, namely solar and wind alternatives. In fact, newly built stations such as the Princess Elisabeth Station, as well as major renovation of existing stations, are consciously working to rely primarily on renewable energy.

As Antarctica moves toward a fossil fuel-free future, the growing dependence on renewable

resources require a reliable infrastructure, and this means reliable pumps.

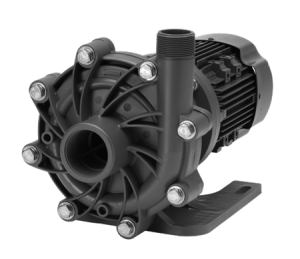

Pumps, specifically sealless centrifugal pumps, are the perfect choice for wind turbines, due to their ability to run for years without a coolant leak. This is particularly important for turbines in remote locations, such as Antarctica. The sealless design not only improves reliability but also enhances safety by preventing the pumped liquid from leaking, a crucial benefit for offshore wind turbines where environmental protection and operational continuity are paramount.

Solar power, which accounts for 1/3 of the renewable energy worldwide, also requires pumps to harness the energy they generate. Solar cells require fume scrubbers to neutralize the chemicals used in the solar energy process and then safely vent them. To operate, these scrubbers require heavy-duty pumps.

If a pump quits due to a seal failure or other malfunction, the fume scrubber stops, and the solar cell manufacturing tool shuts down to prevent the toxic chemicals from being released untreated. This results in extremely costly downtime while the pump is being repaired or replaced. To prevent this occurrence, many scrubbers use corrosion-resistant mag-drive pumps.

At Finish Thompson, we have pumps that support the water, wastewater, and renewable energy industries across the globe. We support wastewater management at virtually every step of the treatment process, from unloading chemicals from tank trucks to bulk storage and from bulk storage to day tanks to emptying batch treatment tanks.

Additionally, FTI is ideally suited to maintain system integrity in a variety of green energy applications. From wind turbines and solar panels to flow batteries and fuel cells, our comprehensive line of industrial chemical pumps combines durability and versatility to provide essential components for a full range of sustainable energy applications.

Antarctica truly is one of the final frontiers in our world. And pumps are an important key to keeping this unspoiled continent clean and vibrant for years to come.

Source: Finish Thompson Inc.