Smaller Jacket Size, Good Heat Loss Performance: Uponor Ecoflex VIP Pipes

Ecoflex VIP already combines the best heat loss performance and flexibility for foam insulated pipes on the market. At ISH 2025, GF Building Flow Solutions introduced a high-flexible version, tailored to medium to large sized local heat distribution network applications, where the pipe size reduction is critical. (Image source: GF Building Flow Solutions)

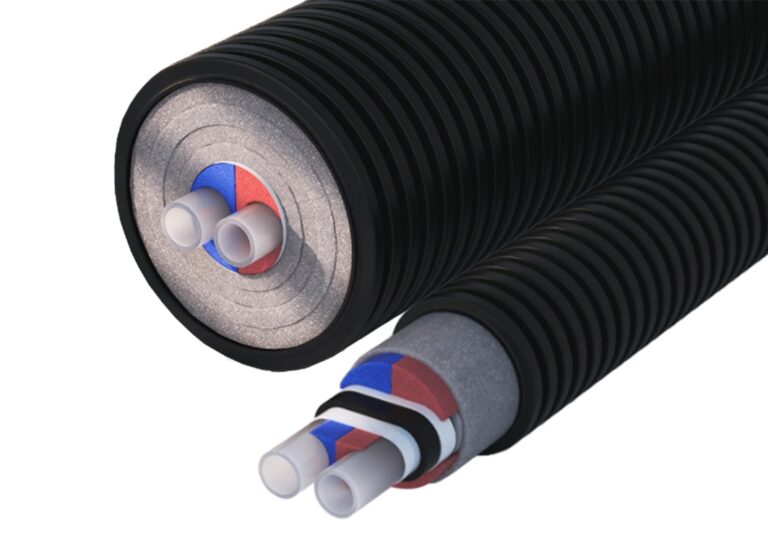

The new generation of Uponor Ecoflex VIP pipes: up to 60% less heat loss and 70% smaller jacket size (compared to similar heat loss and jacket size with PE insulation).

EU’s ambitious sustainability and decarbonization goals require more energy and cost-efficient installations for local and district heating. However, installation complexity slows down the development of alternative high-performance solutions. Additionally, the decline in skilled labor and rising installation costs require more flexible and easier-to-install solutions. “With the new generation of our Ecoflex VIP pipes, we introduce our most efficient heat distribution pipe ever”, says Torsten Meier, Chief Innovation Officer, GF Building Flow Solutions. “It is designed for medium-to-large sized local heat distribution network applications, where the outer pipe size reduction is vital. By leveraging cutting-edge Vacuum Insulated Panel (VIP) technology, this innovation delivers unmatched thermal performance with a significantly smaller outer pipe diameter, making installation faster, easier, and more sustainable.”

Better insulation, less energy loss in the heating network

District heating systems can range from large city-wide networks, using primary pipes up to 1000 mm in diameter, to smaller systems, serving just a few buildings with pipes as small with 25mm in diameter. The system’s size adapts to the area’s needs, from full cities to small neighborhoods. “District heating is becoming increasingly popular with municipalities, planners and construction companies, as it is considered a useful tool to reach EU’s ambitious sustainability and decarbonization goals,” says Torsten Meier. “Nevertheless, typical annual heat losses are around 10%, though it can range from 3% to 30%. The insulation performance of the pipe is crucial for the system’s overall energy efficiency.” Primary networks typically use rigid pre-insulated steel pipes, while smaller networks and secondary systems use flexible pre-insulated plastic pipes for better adaptability and efficiency. “By customizing pipe sizes based on demand, district heating networks provide efficient heat distribution, ensuring optimal energy use without unnecessary waste.”

Vacuum Insulated Panel (VIP) technology from aerospace

“Innovation can be continuous improvement of the core products or taking a major evolution leap – both are applicable with our new generation of pre-insulated pipes”, says Torsten Meier. “This ongoing evolution is a result of learning from advanced technologies in other fields such as aerospace, where the Vacuum Insulated Panels are also used, where the thickness-isolation ratio is a key factor, as every single gram and millimeter counts.”

Tailored to residential and commercial applications

The new generation of Ecoflex VIP pipes provides a 70 % smaller jacket size and an up to 60% improved heat loss (comparison with similar jacket size/heat loss with PE insulation). The VIP panel provides a Lambda of 0.004 W/mK. Offering the full range from Ecoflex VIP Twin 2x25 mm up to 2x75 mm and Ecoflex VIP Single 40 mm up to 160mm, GF Building Flow Solutions meets the growing demand for scalable and ecofriendly heating networks in residential and commercial applications.

Advantages beyond technical performance

Smaller and more flexible, the pipe provides up to 50% installation time saving (compared to steel pipe installation and up to 20% time saving compared to stiff pre-insulated pipes). “Smaller jacket size means easier handling, storage, waste, and reduced installation time and costs”, says Torsten Meier. “No more heavy machinery needed to lay the pipes, and the workers are also relieved as the pipes are much more flexible. Reduced pipe size leads to reduced overall roll sizes and less packaging material. As they are manufactured in GF Building Flow Solutions’ carbon-neutral manufacturing site in Hassfurt, Germany, the solutions for more sustainable local and district heating networks are also sustainable in themselves,” says Torsten Meier.

Source: Uponor GmbH