Siemens presents expanded Digital Enterprise portfolio for the next step in digital transformation

Integration of cutting-edge technologies into the Digital Enterprise portfolio enables flexible and intelligent production. (Image source: Siemens Aktiengesellschaft)

Siemens presents numerous innovations for the discrete and process industries as well as for energy and building infrastructure. The integration of cutting-edge technologies such as edge and cloud computing, artificial intelligence or additive manufacturing into the portfolio offers users new opportunities to achieve more flexible and intelligent production. Communicative networking through Industrial 5G plays a key role.

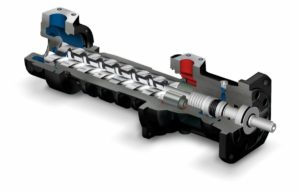

This year’s product innovations include the Sitrans MS Multisensor, which is used primarily for the condition monitoring of mechanical plant components such as pumps, compressors, gears and valves. Through the AI-based analysis of sensor data such as vibrations and temperatures, important information can be generated for predictive maintenance. The user can access machine KPIs and status messages via mobile devices or cloud applications. Siemens is also showcasing four applications for the Closed Loop Digital Twin. They can be used to exchange data in both directions between Teamcenter, Tecnomatix Plant Simulation, Amesim and MindSphere for the continuous improvement of the quality of physical models and simulations. Another new product presented by Siemens is an innovative IoT gateway between cloud, in-house IT and production: Simatic IOT2050 will feature edge functionality in future, meaning that it can be integrated easily into Siemens Industrial Edge solutions.

In the field of drive technology, a solution demonstrates how high-frequency data can be processed close to the machine in future. The connection of Sinamics frequency converters to an Edge device enables users of machines and applications to perform complex analysis of data that is already collected in the drive. Machine learning algorithms identify patterns and detect anomalies and their causes, providing early indications of necessary maintenance, which minimizes downtimes. In the field of AI-based services, Siemens also presents “Predictive Services for Foundry”, which enable users to increase overall plant efficiency in the automotive sector.

In order to increase the efficiency in industrial energy supply and energy consumption, a connected ecosystem of power grids, buildings and industry is required. At the Hannover Messe Siemens presents solutions for the interaction between intelligent power grids and consumers as well as IoT-based systems and services for the energy and building infrastructure in the digital factory.

Source: Siemens Aktiengesellschaft