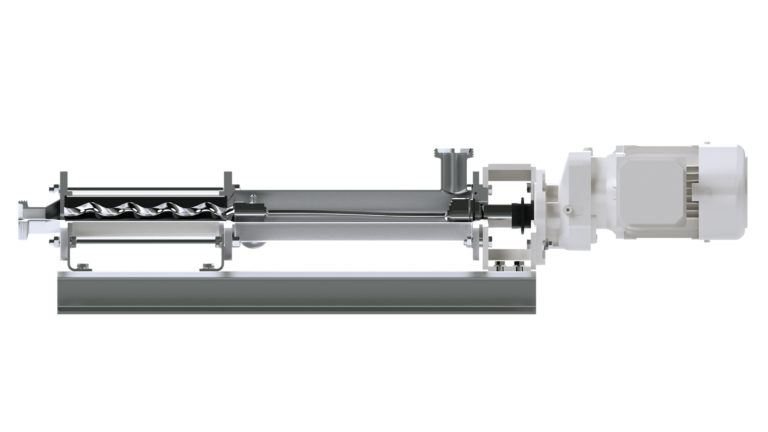

Seepex Launches Sanitary Progressive Cavity Pump with Flexible Rod Drive Train Design

Seepex Launches Sanitary Progressive Cavity Pump. (Image source: SEEPEX Inc.)

The hygienic design is based on a flexible titanium shaft, the Flexrod, instead of a coupling rod with universal joints. The design ensures residue-free cleaning by Clean in Place (CIP) and Clean on Place (COP) processes. CIP cycles are shorter, and COP is simplified by easier disassembly of the rotating parts without needing to disassemble the Flexrodconnecting rods or joints. Additionally, the Flexrod is held in place with food grade fasteners that only require standard hand tools for disassembly.

Further benefits of the BCF range include:

- Increased safety - eliminates the possibility of metal contaminating food products

- Durable - more corrosion resistant than 300 series stainless steel

- Easier to service - fewer parts than in other designs

- Less wear - no rubbing components eliminates the need to replace coupling rods

Seepex’s line of CS progressive cavity pumps, which includes the BCF, are used where cleanliness and hygiene are of the utmost importance. They satisfy the highest requirements with regard to sanitation, gentle conveying, cleaning and sterilization. The CS line can transfer media of both high and low viscosities, with a gentle pumping action, resulting in low product shear and stable conveying capacity and pressure.

Existing BCS pumps can be upgraded to the BCF design by simply changing the wetted rotating parts. The external dimensions and pump casing are identical, requiring no further adaptation of the suction/discharge pipe or mounting footprint.

Source: SEEPEX Inc.