Q-PAC Redefines HVAC Speed, Simplicity, and Reliability with Multimotor Plenum Fan

Q-PAC Redefines HVAC Speed, Simplicity, and Reliability with Multimotor Plenum Fan (Image source: Q-PAC Systems Inc.)

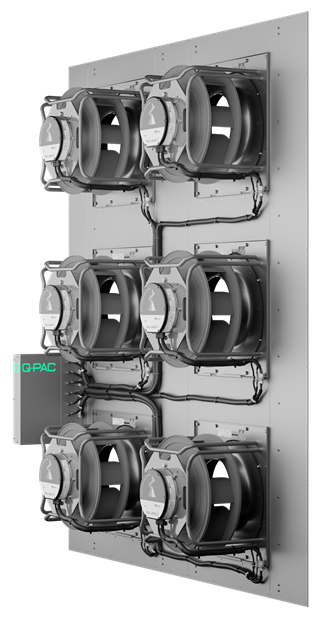

Designed as a single, cohesive system, rather than a loosely assembled fan array, the Q-PAC Fan delivers superior airflow and built-in resiliency for critical infrastructure in healthcare, education, data centers, commercial towers, and other high-demand, comfort cooling environments. This resiliency ensures that if one motor within the system fails, the remaining motors can automatically adjust to keep the fan running without interruption. This eliminates the risk of a full system shutdown and ensures continuous airflow, even during unexpected equipment or environmental issues.

Unlike traditional belt-driven blowers or conventional fan arrays that require complex field wiring and have multiple points of failure, the Q-PAC Fan is a single, well-engineered product with zero points of failure. Its compact footprint and simple assembly make it easier to transport, install, and maintain, even in space-constrained retrofit environments. The unit arrives pre-wired as a complete kit, eliminating much of the coordination and labor associated with fan assembly or blower replacement.

The product also easily connects with building management systems through Q-PAC’s patented Fan Controller, which consolidates all system data and communication protocols into a single connection point. Available in drop-in or knockdown configurations, the Q-PAC Fan supports a fast turnaround, from configuration to shipment, that outpaces traditional HVAC fans. With standard production completed in just three weeks and an optional 48-hour quick build for emergency applications, Q-PAC builds every fan to order and delivers unmatched speed in the HVAC fan market. This industry-leading speed-to-market offering is particularly beneficial for facility managers facing urgent replacement needs in high-stakes environments such as healthcare, education, transportation, and commercial real estate.

In a recent project with the Pennsylvania Liquor Control Board, Q-PAC’s Multimotor Plenum Fan achieved a 48% energy savings compared to the facility’s legacy fan system. Beyond energy efficiency, the Q-PAC Fan reduces labor costs by eliminating belts, grease, and bearings, significantly lowering the system’s total cost of ownership.

With full design, manufacturing, and testing performed in-house within the USA, Q-PAC maintains complete control over product quality and performance. Each fan is backed by a five-year warranty, and supported by Q-PAC’s dedicated team of engineers, who provide fast, knowledgeable assistance throughout the product lifecycle.

By eliminating complexity and delivering dependable, on-demand airflow, Q-PAC’s Multimotor Plenum Fan offers a modern solution to the longstanding challenges of commercial fan systems.

Source: Q-PAC Systems Inc.