Purely Dynamic: Compact Motors With Attached Electronic Controller

WEG recently added Württembergische Elektromotoren’s products to its portfolio. One of the highlights is the UEX series of high-performance, compact motors with attached electronic controller.

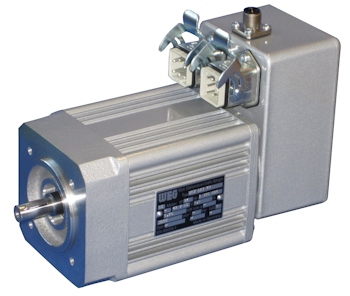

The VD series of high-efficiency IE3 three-phase induction motors with rated power up to 370 W. (Image: WEG)

WEG has added the electric motors and gear units of Württembergische Elektromotoren (Balingen, Germany) to its product portfolio. The product line of the new subsidiary includes the UEX series of electronically commutated (EC) compact motors with attached four-quadrant electronic controllers, and extends WEG’s offering, enabling customers to benefit further from a wide selection of energy efficient motors that best fit their application.

These compact EC motors with CANopen interface cover the power range from 60 to 250 kW and run at speeds up to 3,000 rpm. They are available in versions with an attached gear unit (UEXG 3.3 TH and UEXG 513 TH) or as bare motors (UEX 3.3 TH and UEX 513 TH), with IP54 protection rating. The UEX series of compact EC motors with attached electronic controller are designed as standard for a supply voltage of 24 V DC or 42 V DC and can be operated from a power supply. They feature high overall efficiency and a perfect match between motor and controller. With electronic controller mounted directly on the motor, installation at the user site has been simplified.

Low mass moment of inertia gives the compact motors especially good dynamic characteristics, and the attached electronic controller makes it easy to adapt the motor to various drive tasks. The standard operating mode is speed control, but the compact drives can also be used for torque control or positioning tasks. Hall commutation sensors are used for motor speed control. The electronic controller and the motor communicate with each other over the CAN interface, while communication with the drive is via the CAN bus or digital inputs. The compact motors have several monitoring circuits: temperature monitoring to protect the winding and the electronics, speed monitoring, and overvoltage/undervoltage monitoring.

The EC motors generally have outstanding properties. They combine the low maintenance of three-phase induction motors with the good control characteristics of DC motors. They also deliver constant torque over the entire speed range and achieve both high efficiency and high power density. Their dynamic characteristics include high starting torque, low running noise and good short-term overload capability – up to 1.6 times or 4 times the rated torque, depending on the motor type. The standard UE series of EC motors is designed for operation from 230 V, 50/60 Hz. The controller is powered directly from the mains, eliminating the need for a transformer.

Another highlight in the product line is high-efficiency three-phase motors in the SD series (without fan) and the VD series (with fan), which cover the power range from 50 to 350 W or 90 to 370 W, respectively. They conform to the IE3 Premium Efficiency specification and are amongst the most energy-efficient three-phase motors for low power levels up to 370 W. Thanks to optimised motor design, these energy-saving motors are up to 25% more efficient than standard three-phase induction motors of the same rated power.

Externally, the motors differ from WEG s proven standard motors by their smooth housings without cooling fins. The combination of a smooth surface and IP54 protection combats the accumulation of dirt and bacteria. Therefore, the motors are particularly suitable for all application areas where cleaning is performed with water and cleaning agents, because they can be cleaned together with the rest of the system. This encompasses all clean industries, including beverage, biochemical, food, pharmaceutical, cosmetic, photovoltaic, electronic and medical technology.

WEG acquired Württembergische Elektromotoren Ltd. in early 2014. The production plant in Balingen, Germany, is located approximately 75 km south of Stuttgart, manufactures gear units, three-phase and single-phase motors with rated power up to 1,000 W, DC motors, EC motors and servo motors.

Source: WEG Germany GmbH