Pumps Spare Parts Management Based on Criticality

Pumps under warranty period are not a head ache for procurement managers as the frequency of failure is quite low. But in case of older pumps, spare parts should be available on site to keep the plant operational when it breaks down. It would also be difficult to predict the right number of spare part inventory that needs to be kept on-site since there is a high frequency of failure and the equipment could be out of warranty period.

It will increase the burden of deciding as to what kind of spare parts should be kept on-site and what the minimal number of spare parts on site should be. Segregating spare parts based on its criticality in plant operations helps plant managers consider the strategies for effective spare part inventory management.

Criticality Analysis:

How do you define critical spare parts?

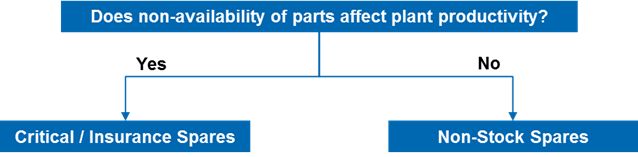

If the non-availability of spare parts affects the plant productivity, it is categorized as critical or insurance spare parts. For example, the replacing of a broke down impeller on time is much more critical when compared to replacing base plates. Likewise, if the non-availability of spare parts does not affect the productivity, it is categorized as non-stock spare parts.

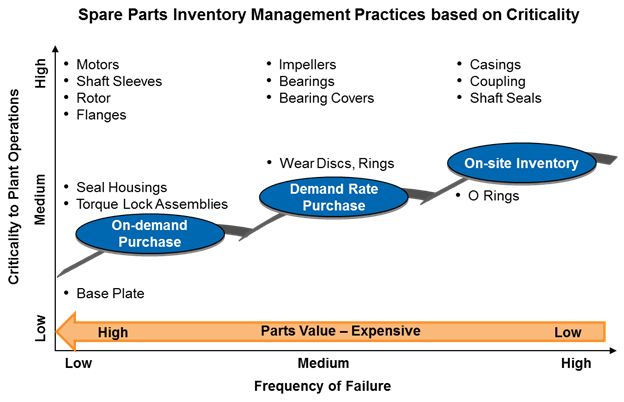

In case of industrial pumps, the criticality is the trade-off between the value of the spare part and its frequency to fail. And the non-stock spare part is defined in terms of minimum level of parts to be kept in inventory in order to avoid inventory holding costs and higher lead time if any.

How do you choose pump maintenance practices?

Criticality analysis also helps an immature procurement organization in choosing different maintenance practices such as reactive, preventive, predictive and proactive for different kinds of industrial pumps based on the impact pumps have in plant operations.

For example, not every pump would need to undergo proactive maintenance or reactive maintenance. The buyers should group the plant equipment in such a way that high critical equipment undergo proactive maintenance as well as low critical equipment are kept under reactive maintenance. Also, it is recommended to adopt preventive and predictive maintenance practices for moderate level critical equipment.

Spare Parts Inventory Management:

Case 1: On-site Inventory – Critical Parts

These parts have to be kept in inventory at all times in order to keep the plant running.

Some of global pump manufacturers offer consignment stock offerings to their key account buyers. E.g. KSB, Sulzer. It is good to have a consignment stock model for critical spare parts.

E.g. Casings, Coupling, Shaft Seals, and O-Rings

Demand Rate Purchase

Moderate critical parts are purchased based on historical demand which is a function of frequency of failure, lead time and life of the pump.

E.g. Impellers, Bearings, Bearing Covers, Wear Discs and Rings

Case 3: Order On-Demand – Non-Stock Parts

These parts are usually not stocked up with more than one in number because they prove to be expensive. Their frequency of failure is comparatively low.

E.g. Motors, Shaft Sleeves, Rotor, Flanges, Seal Housings, Torque Lock Assemblies

Ideal Spare Parts On-Site Inventory:

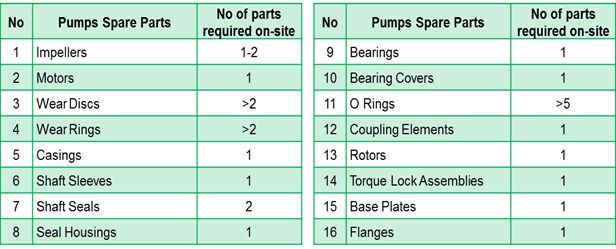

The following table represents the number of spare parts required on-site at all times in order to keep the plant running. Frequencies of failure and part value are fundamental at arriving at this decision.

Note: Number of spare parts required for a centrifugal pump of operating pressure 10 bar. It is subjected to medium to be pumped, life of the pump, and the nature of the operation.

Conclusion:

A major chunk of procurement costs goes into sourcing the spare part. It is wise to keep an optimum number of spare parts on-site in order to save on inventory holding cost and storage space. This also helps save time to repair the broke-down equipment in order to get it back in operation as soon as possible. For an immature procurement organization with limited in-house technical sources, the criticality analysis helps discern the kind of spare part that needs to be kept on-site vs. at the supplier’s warehouse. It also helps prevent obsolescence among on-site spare parts.

Author: Anusuya Ramadoss

Source: Beroe Consulting (I) Pvt. Ltd.