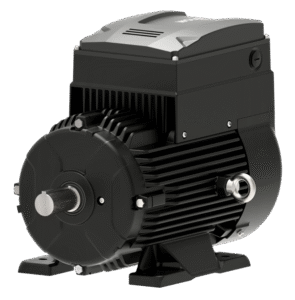

Permanent Magnet Direct Drive Motors to Modernize Industrial Airflow Systems

Advanced Motor Design Improves Efficiency, Reliability, and Longevity while Reducing Maintenance and Energy Costs (Image source: Wolong Electric America)

Permanent Magnet Direct Drive (PMDD) Motors eliminate the need for belts and sheaves by employing a direct drive design, drastically reducing mechanical complexity and removing common points of failure. This simplicity lowers maintenance costs and increases reliability, delivering significant operational advantages. At the heart of each unit is a rare earth magnet core that generates stronger magnetic fields and enables a more compact footprint, while offering superior efficiency and performance compared to traditional ferrite-based options.

The PMDD is operated by a variable frequency drive (VFD), ensuring precision control and supporting smooth acceleration and deceleration, reducing energy spikes, and extending system life. The motors also feature a 4:1 turndown ratio, allowing them to maintain torque and efficiency even at low speeds, an ideal solution for variable demand conditions and ambient system adjustments.

By eliminating belts, this direct coupling to fans significantly lowers radial load on bearings and reduces mechanical stress. With approximately 20% greater efficiency than conventional induction motors, users can realize dramatic energy savings. These motors also deliver smoother startups with no inrush current, reducing electrical strain and enhancing equipment longevity. This is especially valuable in large-scale or sensitive installations.

Thanks to the combined benefits of reduced maintenance, longer service life, and ultra-high energy efficiency, PMDD motor users will experience significantly lower total cost of ownership.

Permanent Magnet Direct Drive Motors operate much cooler than induction alternatives and are designed for long-lasting durability. They can also be custom-engineered into configurations tailored to specific application needs, whether for data centers, refineries, or OEM-designed equipment such as heat exchangers. Wolong Electric America’s approach supports easy integration with OEM and packager systems, helping streamline supply chains and service support.

Future-ready and built with evolving regulations in mind, Permanent Magnet Direct Drive Motors position OEMs to meet or exceed anticipated Department of Energy efficiency standards. Whether modernizing legacy equipment or building new systems with longevity and efficiency at the forefront, Wolong Electric America’s PMDD Motors offer a forward-looking solution that replaces outdated conventions with a high-performance, regulatory-compliant alternative.

Source: Wolong Electric America