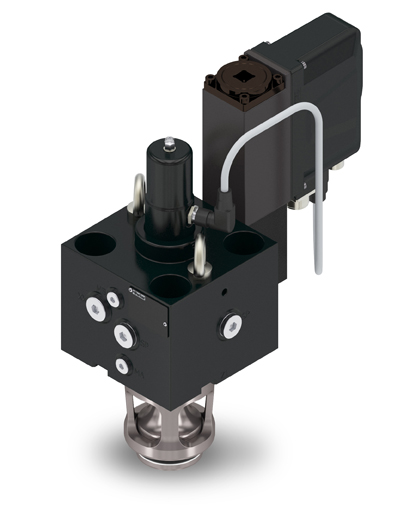

Parker Is Introducing the Enhanced Version of Proportional Cartridge Throttle Valves

Faster than ever before: the new TFP with DFplus generation IV pilot valves shorten step response by up to 30%. (Image source: Parker Hannifin GmbH)

Together with the innovative design of the sleeve and spool that allows for previously unattainable volume flow and pressure drop values, the TFP series enables shorter cycle times, more stable processes, and minimized scrap rates.

The new dual-core processor in the DFplus generation IV pilot valves enables them to run at maximum performance while simultaneously communicating with the PLC, and the retention of the analogue command signal combined with the valve's standard IO-Link connection for communication is unique. This advancement allows for a further shortening of the acceleration phase of the shot cylinder in a die casting machine, thereby enabling the production of structured and large-area die cast parts with high and repeatable quality.

An integrated near-field communication (NFC) chip allows users to obtain all status information in the field or in service situations with a mobile device like a mobile phone or a tablet – even when the valve is not actively powered. The “Parker Device Connect” app, available for free, enables communication between the valve and the mobile device. Additionally, a 360° LED at the top of the electronics box ensures that the basic status data is immediately visible in the application by different colors or flashing frequencies.

The main stage of the TFP series, which was launched in 2021, remains unchanged. The valve is characterized by a pressure-compensated sleeve with an enlarged seat diameter and oriented windows, which almost completely uses the DIN cavity. Along with a maximum pressure of 420 bar, this results in exceptionally high flow values of up to 25,000 l/min, depending on the nominal size.

Thanks to the modern controller structure, the new pilot valve makes it possible to shorten the step responses by up to 30% while maintaining the precise opening and closing behavior. This achieves larger volume flows in a shorter time, which increases performance in demanding applications such as die-cast machines and presses.

With the new DFplus generation IV pilot valve, Parker’s TFP cartridge valve series is the fastest in its class. These improved properties further extend the range of applications for the valves. Nevertheless, the valves are also suitable as a 1:1 replacement for TFP valves with DFplus generation III valves.

Source: Parker Hannifin GmbH