OEM-X Line Universal Pump Repair and Retrofit Service Launched

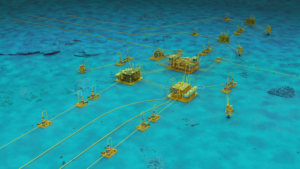

Sulzer is launching OEM-X line - the only 24/7 quality pump service with flexible repair and retrofit solutions for any pump brand. (Image source: Sulzer Ltd.)

Available anywhere, anytime and ready to support any pump requirement - OEM-X line is backed by Sulzer’s global design and engineering capabilities. This comprehensive offering of turnkey repairs and upgrades for pumps improves asset performance and reliability, whilst ensuring operators are equipped to meet the pump challenges of today and tomorrow.

Whether quickly reacting to a breakdown, attaining higher efficiency standards, meeting a new duty point, accommodating a change in process or extending service intervals – every pumping system has unique requirements. With the numerous brands, types and ages of pumps working in applications across industry, operators need a trusted independent service provider (ISP) that can meet every demand.

Giving you the right options for your needs

Sulzer’s OEM-X line offers the best quality pump overhaul, retrofit, upgrade, field service and part manufacturing solutions on the market available from a single source. Leveraging unmatched heritage and expertise from a global pump manufacturer, OEM-X line provides total asset support, backed by a global network of service centers and manufacturing facilities, all accessible around-the-clock.

A worldwide team of experts offers instant familiarity with equipment and application, flexibly working to define the appropriate repair or retrofit approach in terms of quality, speed of delivery and value. Data driven analysis, inspections and reports allows operators to make informed decisions, while the all-in-one package for servicing and parts manufacture means that the perfect, bespoke solution is always attainable. With unsurpassed reverse engineering, finite analysis, 3D laser scanning and retrofits all available at local facilities globally – operators can always get the support they need.

The go-to for any industry challenge

As well as in-house engineering support administered from over 100 service centers, dedicated field service teams are ready to rapidly respond to any pump application challenge. Engineers with experience across the power generation, water, energy, industrial markets and more deliver monitoring, fault diagnosis, testing and inspection for pumps in-situ.

More than that, OEM-X line is tailored to overcome specific industry challenges. Retrofits can allow pumps to reach new efficiency standards, so operators can stay ahead of tightening carbon tax legislation. Local support and sourcing avoids supply chain disruptions and long lead times, helping utilities to keep essential services online. Pump modifications enable equipment to reliably adapt to the changing duty points synonymous with the renewable energy transition. In all cases – a local Sulzer team will be ready to help.

“We are a global pump expert, not just for our own models, but for any branded pump,” says Ravin Pillay Ramsamy, President, EMEA, Sulzer Services. “We are a technological leader when it comes to the manufacture and upgrade of pumps, which means we are perfectly placed to improve equipment for our customers. OEM-X line demonstrates our commitment to optimizing any process, combining the knowledge of a market-leading OEM with the capabilities of a world-wide ISP.”

Source: Sulzer Ltd.