New Pump Series Delivers Reliable Performance for Challenging Solids and Dry Sludge Handling

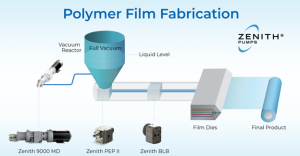

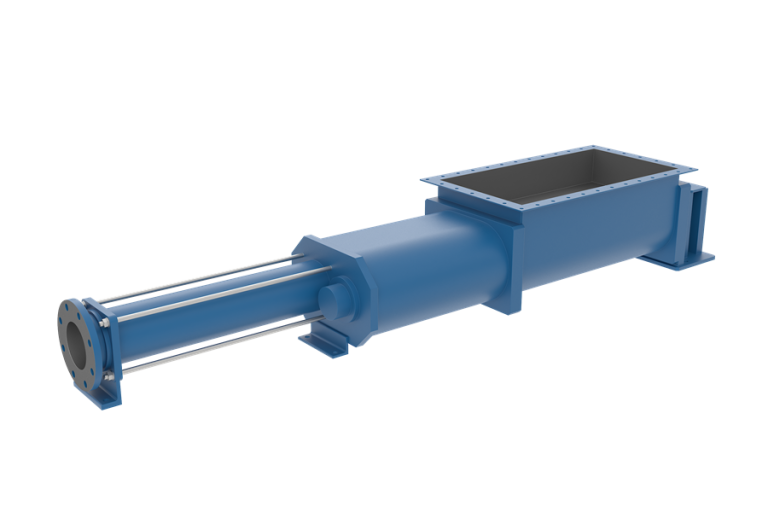

The ALLWEILER AE-RG Hopper Pump Series is engineered for efficient and reliable transfer of highly viscous, abrasive, or solids-laden materials, making it ideal for demanding environments such as wastewater treatment, especially dry sludge handling, biogas, and various other processing applications. (Image source: CIRCOR International, Inc.)

The AE-RG Hopper Pump Series features an optimized hopper design that provides smooth and efficient transfer of materials, including substances with up to 45% dry solids content. This robust approach ensures a continuous pumping of non-free-flowing, dewatered, or fibrous products, ranging from high viscous and sticky starch to highly dewatered and solid-laden municipal sludge. The series leverages progressing cavity pump technology to seamlessly handle the most challenging media, promoting lasting, dependable operation in challenging settings. Each pump includes two intermeshing augers. The two augers are optimized for every application and can be designed either as mixing or conveying screws; even a mix of both types is possible. This prevents bridge building and clogging at the inlet hopper, guaranteeing uninterrupted performance even with difficult-to-handle materials, without the need of separately-driven and energy-consuming bridge-breakers. The option of mixing screw design also allows customers to add conditioning agents or other additives through a bypass line into the inlet hopper and get it blended into the main pumping media.

Another key design feature is the generously dimensioned stuffing area between the hopper and rotor/stator, which allows for optimal overloading of the feed screws. This ensures nearly complete filling of the conveying chambers between rotor and stator, effectively eliminating the risk of partial dry running. As a result, wear on critical components such as rotor and stator is significantly reduced, leading to fewer operational interruptions, lower spare parts consumption, and substantial savings in operating costs.

Furthermore, maintenance efficiency is a key advantage of the AE-RG Hopper Pump Series. The maintenance-in-place design allows for on-site maintenance without full pump removal, minimizing costly downtime and simplifying routine service needs. Patented dry run protection integrates advanced safety controls for automated pump protection, reducing the maintenance workload and risk of damage. The low overall height makes integration into new or existing plant layouts simple and versatile, and a maintenance-free sealing paired with a robust gearbox bearing maximizes reliability and operational uptime. Additionally, cleaning and inspection are streamlined by external flushing ports on the inlet and stuffing casing.

With capacities up to 560 liters per minute and pressure ratings up to 24 bar, the ALLWEILER Hopper Pump Series delivers consistent, pulsation-free flow even under high demand and at fluid temperatures up to 135 degrees Celsius. This combination of features enables process operators to achieve trouble-free pumping of problematic materials and supports continuous operation, improved process control, and productivity across a wide range of industrial and municipal environments.

Source: CIRCOR International, Inc.