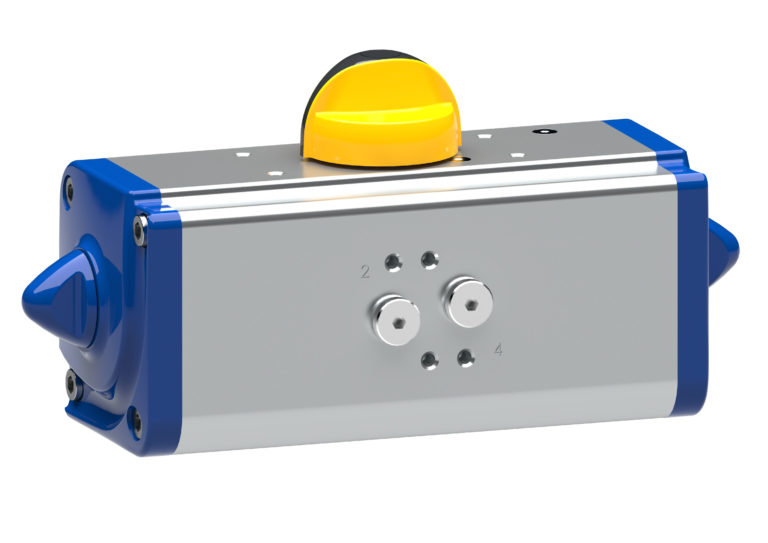

New Pneumatic Quarter-Turn Actuators

Double-acting and single-acting pneumatic actuators of the ACTAIR EVO and DYNACTAIR EVO type series from the KSB Group. (Image source: KSB SE & Co. KGaA)

Applications covered by the actuators are water treatment, waste water treatment, power generation, general industry, refinery engineering and shipbuilding.

The double-piston actuators can be operated with compressed air to ISO 8573-1 from 3 to 8 bar. The maximum torque is 8000 Nm for the double-acting type series and 4000 Nm for the single-acting variant. The maximum ambient temperatures should be between -50 °C and +150 °C. With their IP68 enclosure, the actuators are suitable for use in a maritime environment. This means that – in the event of flooding – they will remain water-tight for about 169 hours at a depth of up to 30 metres.

The pneumatic connections comply with the NAMUR requirements. For mounting the necessary control units, every actuator is designed with interfaces to the VDI/VDE 3845 standards. Connection to the valve is via an ISO mounting interface to ISO 5211. The scotch yoke mechanism of these pneumatic actuators provides a variable torque, with the peak torque being effective for closing the valve.

As standard, the actuator is fitted with a position indicator and adjustable mechanical stops. The actuators are lubricated with silicone-free grease at the factory, their gear housings are made of anodised aluminium alloy. With their standardised interfaces, the actuators can be connected to higher-level process control systems with solenoid valves, positioners and diverse digital and analogue control units.

Source: KSB SE & Co. KGaA