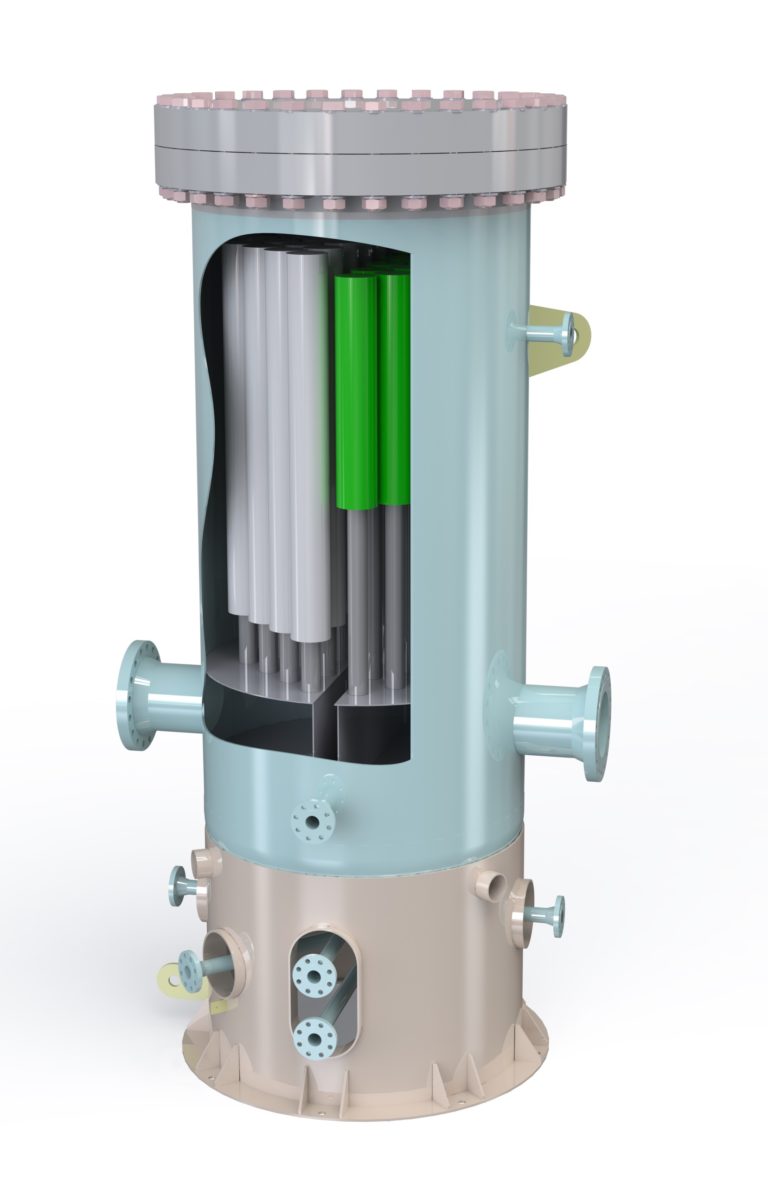

New Liquid/Liquid Coalescers from Celeros Flow Technology

New Liquid/Liquid Coalescers from Celeros Flow Technology pass the test for improved filtration performance, reducing TCO. (Image source: Celeros Flow Technology)

UNIQ-FLOW L/L coalescers are designed to help customers improve product quality, reduce or remove unwanted haze and impurities, and recover other valuable products. Typical applications include bio-fuels, condensate cooling, MEG removal, amine gas sweetening, removal of water from diesel, kerosine or condensates, recovery of hydrocarbons from water, and glycol applications.

Commenting on their introduction, Chris Nixon, Head of Filtration at Celeros Flow Technology, says: “Market demand for higher quality products and prolonged periods of uptime mean that flow control equipment like coalescers has to work more accurately and more reliably for longer. We tested our UNIQ-FLOW Liquid/Liquid Coalescers against their nearest rivals in the market to validate their performance and the results are impressive. Customers can be confident that they will benefit from superior performance, reduced maintenance and lower lifecycle costs.”

Tried and tested

UNIQ-FLOW L/L Coalescers were performance tested against their nearest rivals in the market using ASTM test standards and jet fuel as the test medium. The test results showed that UNIQ-FLOW L/L Coalescers not only meet, but exceed, the in-service efficiency threshold of 20ppm stipulated in many leading end user specifications. In fact, the new coalescers can meet even more stringent <10ppm thresholds.

Droplet sizes observed during testing were considerably larger than expected, which shortens the separation distance significantly and reduces the overall length of the vessel. Flux rate (flow per cartridge) was also higher than originally envisaged. A clear interface between water and fuel and excellent stable droplet formation were also observed.

Superior filtration

Drawing on the expertise inherent in the company’s Dollinger and Plenty brands, UNIQ-FLOW L/L Coalescers are equipped with both pleated polymer & glass fibre filtration media in absolute ratings at 10 microns. They are available in standard size ranges or can be custom designed to meet individual process requirements for optimum performance.

Housing constructions are offered in a range of carbon, alloy, stainless steel and duplex stainless steel materials with alloy 625 / 825 overlayed materials. Each unit is designed specific to end user code requirements including ASME U-1, PED, GB-150 and PD5500, amongst others.

Source: Celeros Flow Technology