New GEMÜ CleanStar High-Purity Diaphragm Valve is Setting Standards

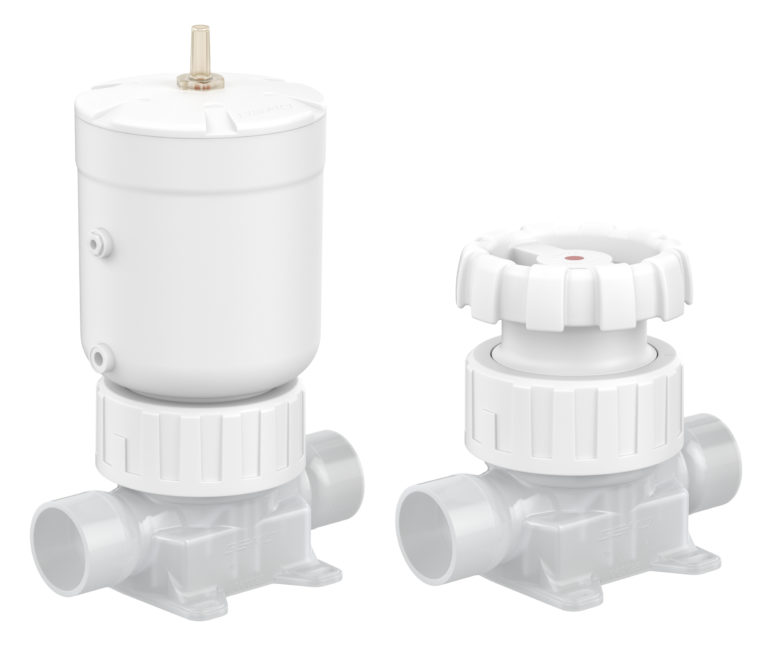

GEMÜ C60 CleanStar, pneumatically operated and GEMÜ C67 CleanStar, manually operated, actuator size 4. (Image source: GEMÜ Gebr. Müller Apparatebau GmbH & Co. KG):

The semiconductor industry's requirements of valve designs are constantly growing. Ever-smaller structures on the microchips require fluids of maximum purity that are free of particles. The required quantity of process media has simultaneously increased over the past years due to wafer diameters becoming larger. GEMÜ takes both of these developments into account with the launch of the new actuator size. The new actuator size 4 is available in nominal sizes 1½" and 2", and the media wetted parts are made of PFA and PTFE TFMTM. This combination allows large media quantities to be transported and ultra pure valve designs to be used even at the supply and distribution level of semiconductor production. The compact GEMÜ CleanStar design simultaneously ensures an excellent flow/footprint ratio and will replace the GEMÜ 600 HP and GEMÜ 677 HP/HPW diaphragm valves in the future.

GEMÜ CleanStar: A tried and tested design conquers new applications

The advantages of the GEMÜ CleanStar series are numerous. The central union nut creates a reliable joint between the actuator and valve body, and does so completely without the use of metal parts. The weir design (weir style) ensures low-stress media channelling, minimizes deadlegs and does not specify a flow direction. The exterior parts display very good chemical resistance due to the use of PVDF. A leak detection hole and slotted holes for flexible installation of the valves are already integrated into the body design. The series also has a position indicator as standard. All these advantages have been adopted when it comes to the scale on the new actuator size 4. Thanks to the larger nominal sizes, GEMÜ is already harnessing all named product advantages for its customers at the supply and distribution level (facility and sub-fab) of semiconductor production.