KHS Introduces New Aseptic Block for Bottle Sterilization

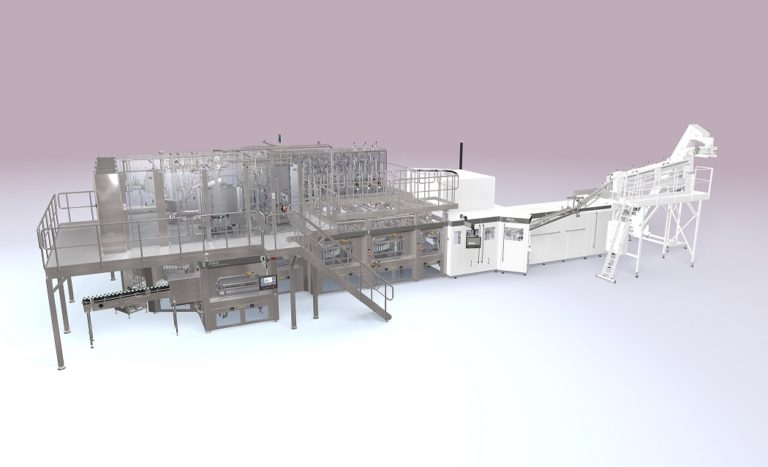

The new rotary InnoPET BloFill ACF-R aseptic block combines the energy-efficient InnoPET Blomax Series V stretch blow molder with the rotary Innofill PET ACF-R filler for the very first time. (Image source: KHS GmbH)

“Economic success calls for maximum efficiency and availability in all filling and packaging processes. We provide innovative and resource-saving systems and solutions that fully satisfy all aspects of this demand,” says Tobias Wetzel, CSO of KHS. The most recent example of this is the new rotary InnoPET BloFill ACF-R aseptic block that combines the energy-efficient InnoPET Blomax Series V stretch blow molder with the rotary Innofill PET ACF-R filler for the very first time.

Linear fillers can process up to 14,000 bottles per hour. In contrast, the rotary aseptic block has a capacity of up to 36,000 1.0-liter bottles per hour and in the future is even to be available with a top output of 48,000 500-milliliter bottles an hour. The new plant engineering achieves a sterility of log 6 inside the bottles – which is equivalent to a reduction in germs of 99.9999%. “Our linear aseptic fillers, also blocked, have long proved themselves in practice in the filling of sensitive beverages into PET bottles, where maximum safety is of the essence. The newly developed rotary aseptic filler in the higher capacity range is thus the next logical step. With this, we also want to set standards regarding the machine’s hygienic properties,” Wetzel promises.

Effective protection for sensitive beverages

Here, KHS consciously focuses on bottle sterilization that – unlike preform sterilization – can also be combined with the KHS FreshSafe PET coating system and thus offers additional barrier protection for sensitive beverages. On this variant all potential germs are removed from the containers directly prior to filling. This process gives bottlers more flexibility and greater availability during format changeovers than preform sterilization, as here changing the stretch blow molds disturbs the sterile state of the block.

The KHS Group will be presenting the Aseptic Block at Anuga FoodTec in Cologne, Germany, from March 19 to 22, 2024.

Source: KHS GmbH