In the Distorted Mirror of Rated Power and the Service Factor

When selecting vacuum pumps, plant designers often strive to get by with the lowest possible rated power for the drive motors. They see this as a way to save power. But when it comes to actual energy efficiency, the kilowatt specification on the name plate can be quite misleading.

Because the actual power consumption is only partially reflected in the motor’s rated power. Further confusion is caused by the “service factor” that is included on some name plates and puts the actual rated power into a different context. Its significance is often misunderstood. The highest possible energy efficiency can only be achieved with systematic analysis.

The essential variables for the selection of a vacuum pump are ultimate pressure and pumping speed. These factors determine the vacuum level that will be achieved in a certain period, or which “vacuum performance” is therefore available in the application.

Comparable performance can be achieved with vacuum pumps that have very different operating principles. In the process, the speed can also differ dramatically. For instance, this becomes clear by looking at the motor speed: a rotary vane vacuum pump, which is currently the most common form of vacuum technology, uses 1,000 rpm to achieve a similar vacuum performance to an oil-lubricated screw vacuum pump with up to 7,000 rpm.

Rated power ≠ power consumption

A further difference can emerge by looking at the name plate: for example, a screw vacuum pump can indicate lower electrical rated power than a rotary vane vacuum pump. When selecting devices, a mistake that is frequently made is inferring the power consumption from the rated power. However, the motor with the smaller number in front of the kW specification in no way means that it necessarily uses less power than the “larger” drive. Often in practice, the exact opposite is in fact true. On American name plates, the actual rated power is also disguised by the “service factor”.

The narrow focus on the rated power obscures the efficiency of the vacuum pump and the motor.

The relationship between power consumption and the provided performance (shaft power) is not linear for electric motors. They usually achieve optimal performance somewhere between 50 and 100 percent of their rated power. In general, you can assume that the ideal performance or highest efficiency level is achieved in a more or less wide range around 75 percent of the rated power. Below this range, the motor consumes more power in relation to the provided performance; the relative power consumption increases.

Misleading “service factor”

This also applies when the optimal range is exceeded, whereby more than 100 percent of the rated power is also possible. This is where the service factor (SF) comes into play. It is defined as a standard by the US American National Electrical Manufacturers Association in the NEMA MG1-2011 handbook. The service factor is specified on the name plate (fig. 1). It indicates the degree to which a motor can be loaded beyond the rated power. To calculate the permissible degree of overloading, the rated power is multiplied by the SF value. For example, if a rated power of 15.0 kW is indicated with a service factor of SF 1.25, the maximum permissible rated power is 15 x 1.25 = 18.75 kW. Therefore, it is 25 percent higher than it seems at first glance.

Even though NEMA points out that the SF range should only be used temporarily, in practice it is often included in the calculations for normal operation for vacuum generation. This is because quickly starting the vacuum pump from standby mode or short peak loads, even if they are regularly achieved in quick cycles, can be recorded as “temporary” overloading. The relatively low rated power without the calculated service factor suggests low power consumption. But the actual performance used is not only higher; the motor also usually works significantly outside of its efficiency optimum in the SF range. Regular overloading can also shorten its life cycle.

Testing actual power consumption

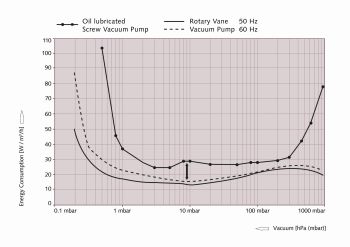

To be able to truly compare the actual energy efficiency of different vacuum pumps, power consumption and performance must be measured in practice. The vacuum pump manufacturer, Busch, performed this type of comparison between a speed-controlled and oil-lubricated screw vacuum pump from another manufacturer with the specified rated power of 15 kW and a service factor of SF 1.25 and a rotary vane vacuum pump from its own range with a rated power of 18.5 kW on the name plate. The result of the test was that the power consumption of the “smaller” motor according to the rated power was nearly twice as high as that of the comparison model in the range of the main load. The rotary vane vacuum pump, which works at a lower speed, achieved substantially better energy efficiency despite its “larger” motor (fig. 2).

Conclusion

The overall efficiency of a vacuum supply requires more complex consideration than merely comparing the energy consumption. In addition to the ultimate pressure and the pumping speed of a vacuum pump or system, the operating principle, whether oil-lubricated or dry-compressing, must be evaluated in-depth and its compatibility with the process must be checked. But the installation location, control or the connection between the process and vacuum generation can also be parameters that influence the energy efficiency and economic efficiency of a vacuum supply. In many cases, a qualified vacuum specialist is needed to select the right pump and design. However, in this process the focus should always be on critical consideration of the actual energy consumption.

There are numerous factors that can range from the spatial placement of the machines, to the process cycle and the option of a vacuum buffer.

Picture: Practical comparison of a speed-controlled oil-lubricated screw vacuum pump with rated power of 15 kW / SF 1.25 and a rotary vane vacuum pump with rated power of 18.5 kW: in the most important operational range around 10 mbar, the pump motor with the lower rated power consumes more power than the “larger” motor of the rotary vane vacuum pump (Image: klartext: von pekker!)

Source: klartext: von pekker!