Going virtual – Sulzer welcomes visitors to its online virtual exhibition stand

Sulzer welcomes visitors to its online virtual exhibition stand. (Image source: Sulzer Ltd.)

Visitors can navigate the stand and its interactive 360° virtual environments from anywhere in the world to learn more about the company’s solutions. Presenting Sulzer’s diverse range of advanced products and services, the digital booth brings the company’s key capabilities together under one (virtual) roof. The stand enables viewers to interact with what is on display, including videos, animations and 3D models as well as brochures and other literature, as if they were on a physical stand. Furthermore, attendees can get in touch with the company’s leading experts to discuss key technologies, solutions and services as well as arrange meetings to discuss specific project requirements.

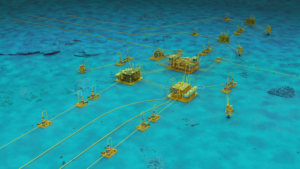

Visitors can explore 1:1, true to scale, photorealistic renders of facilities and equipment that would be impossible to incorporate into a physical exhibition. The stand can be accessed 24/7 using a computer, smartphone or tablet.

Separation and mixing technology

Sulzer’s range of separation, mixing and mass transfer solutions delivers considerable advantages to businesses in the manufacturing and processing sectors. Visitors to the digital stand can learn more about these capabilities, the equipment and applications, by visiting 360°process skids, plants and a column internals showroom.

By visiting the immersive virtual experiences, guests are able to find out more about Sulzer’s fully tested, customizable setups with short delivery times.

Pump technology

An insight into the latest pump designs is also available within the virtual environment. In particular, visitors can benefit from a comprehensive view of solutions that can be provided for different power generation plants.

A key 3D product model on display is the HST 20 turbocompressor. This incorporates a Premium Efficiency motor and digitally controlled magnetic bearings to offer advanced wire-to-air efficiency. Ultimately, this provides excellent reliability and optimizes life cycle costs.

Service solutions

Visitors to the virtual booth can also learn more about Sulzer’s leading rotating equipment services. It's worldwide network of service centers, supported by design, manufacturing and engineering facilities offers turnkey solutions for a wide range of sectors. From steam turbines and compressors to generators and large motors, Sulzer’s experienced team provides a comprehensive service for all rotating equipment across the world.

Sulzer’s experience in the rail sector is brought to life with the virtual passenger train, which offers a unique insight into the company’s comprehensive support for key pieces of equipment. This includes preventative maintenance and reverse engineering of new parts to extend their operational life as well as improve the efficiency and reliability of important assets to minimize downtime and boost productivity.

Dorota Zoldosova, Head of Marketing and Communications at Sulzer Chemtech, explains: “Interactive and immersive digital experiences are becoming increasingly popular and will play a crucial role in shaping the future of industrial events. Sulzer’s virtual stand gives us the opportunity to show how our products and services fit into applications that we could never take to a physical show. We won’t stop hosting and attending live events, but this platform will enable us to strengthen our relationship with existing as well as new customers in between exhibitions and seminars and it is open 24/7.”

Source: Sulzer Ltd.