Fluid Handling Solutions Evolve to Meet Needs of Larger Offshore Wind Turbines

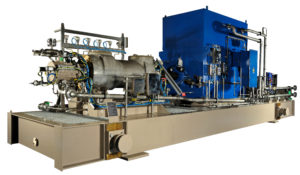

Offshore wind turbines are getting larger. WTIVs and associated flow control equipment must be able to cope with the additional strain of transporting and erecting them. (Image source: Celeros Flow Tech)

As a full lifecycle partner, Celeros Flow Technology is working to anticipate the operational and sustainability challenges of the renewables sector, ensuring that our flow control equipment and services continue to deliver the performance and reliability required to deliver the energy transition.

Offshore wind is a prime example of the new challenges facing flow control equipment. Dogger Bank, the world’s largest offshore windfarm, is currently under construction of the coast of Northern England. It will deploy 277 turbines that are 260m tall. They require a specialist vessel with a lifting capacity of 3,200 tonnes – another world record – to erect them. It is predicted that, by 2030, the industry will be deploying 20MW turbines with rotors of up to 300m in diameter. This growth in turbine size means that essential vessels such as jack-up rigs, self-elevating heavy lift crane barges and WTIVs (wind turbine installation vessels) must be able to cope with the additional strain of transporting and erecting giant turbines.

Raw water (seawater) is critical to activities including drilling, firewater duties, and providing ballast on semi-submersible structures used in offshore wind turbine erection. Maximizing operational life and minimizing total cost of ownership of critical flow control systems is paramount, particularly in offshore installations which are less accessible for routine maintenance. The S&N Pumps range of ESPs from Celeros Flow Technology features high grade construction using robust, corrosion-resistant materials such as stainless steel. A Duplex material grade design is also available. These pumps can be oriented horizontally or vertically and are available in diameters of between 4” and 24”. Equipped with powerful motors up to 750 hp, they can achieve flow rates of up to 4500 gpm.

ESP pumps may also form part of a pre-loading reel system which provides a means of storing, lowering, and retrieving a hose to secure a reliable supply of raw water. Designed to mount directly to the main deck, reel systems are an improvement on mounting the pump in the leg of the crane or platform and make deployment quicker and easier. However, the hoses can stretch, puncture or fracture, and this damage can lead to reel system snagging and related delays in deployment. Failure of a hose system can therefore be extremely expensive and cause major project delays.

Celeros Flow Technology offers a solution that minimizes this risk. The E-Z Fit Reel System from S&N Pumps features a hose with reinforcing wire along its entire length. This reinforced hose will support the combined weight of the pumps, shroud and full water columns, eliminating hose stretch and extending hose life. The reinforcement of the hose is complemented by a custom engineered roller deployment system that intuitively maintains the radius bend of the hose throughout deployment and retraction. The E-Z Fit systems are easily retrofitted to an existing vessel or supplied for new construction.

Source: Celeros Flow Technology