Editorial: The Importance of Default Position in a Valve

Image source: Plast-O-Matic Valves, Inc.

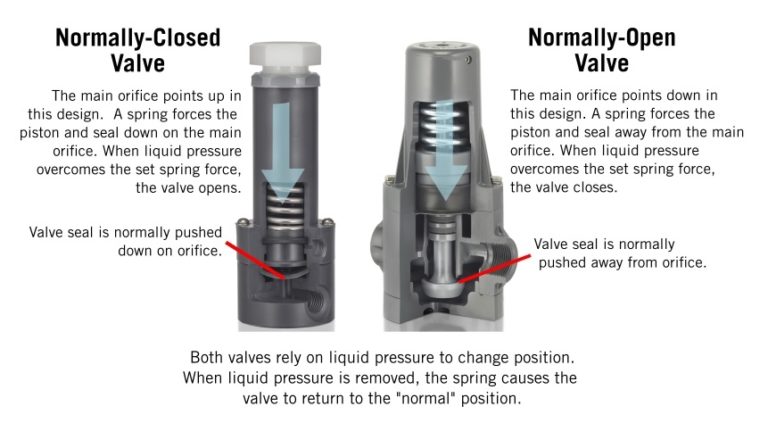

Normally-Closed Valves, Normally-Open Valves, Fail-to-Position Valves

Commonly known as “default position,” actuated or automatic valves that revert to a pre-determined position after the actuating force is removed are often referred to as “fail-safe” valves. The most common type is “fail-safe normally-closed.” “Fail-safe normally-open” valves are much less common, but are equally important. These are often found in cooling systems, or are used where flow is shut off only for periodic maintenance, etc.

Some valves, such as spring-loaded air actuated ball valves, can be converted between types. There are also “fail-to-position” valves, which automatically move to a specific point, including “fail-freeze,” which will remain in place in case of a power failure or other event.

Normally-Closed Valves

An example of a normally-closed actuated valve is Plast-O-Matic’s Series EASMT Solenoid Valve. The valve opens when energized, and when that current is turned off, an isolated spring inside the valve forces it closed. The magnetic force of the solenoid coil must overcome the force of the spring to open the valve. Unless acted upon, the spring force keeps the valve closed. In the event of a power failure, the valve will automatically close.

An example of a normally-closed automatic valve is Plast-O-Matic’s Series CKM Check Valve. The valve opens when pressure is present at the inlet (or upstream) side. When that pressure ceases, the diaphragm inside the valve automatically forces it closed. The inlet pressure must overcome the force of the diaphragm to open the valve. Unless acted upon by inlet pressure, the diaphragm force keeps the valve closed. In fact, the valve closes before reverse flow can take place. (note that the above refers to Series CKM/CKS; most check valves, including ball type, are not normally-closed valves.)

Normally-Open Valves

An example of a normally-open valve is Plast-O-Matic’s Series ARV Air Release Valve. The valve is designed to close when water rises at system start up, and reopens automatically when the pump is shut off and the liquid drains from the piping. Unless liquid is present, gravity keeps the valve open.

Another example of a normally-open automatic valve is Plast-O-Matic’s Series PRHM Pressure Regulator. The valve is set to remain open at a predetermined pressure, and begins to close automatically when downstream pressure exceeds that predetermined pressure. When pressure downstream drops back to accepted levels, a spring inside the valve forces it back open. The downstream pressure must overcome the force of the spring to close the valve. Unless acted upon by excessive downstream pressure, the spring keeps the valve open (see illustration above).

Valves that can be Converted between Normally-Open and Normally-Closed

Air-Actuated, Spring-Return Ball Valves — Plast-O-Matic Series ABVS, ABRS & ABMS — are examples of valves that can be normally-open or normally-closed. In these valves, a rather large spring is used to force the actuator back to its original position, whether that is open or closed.

One of the advantages of a Plast-O-Matic Air x Spring Actuated Ball Valve is that it can be converted fairly easily between one type or the other. Because the spring forces the actuator one way or the other, it is simply a matter of redirecting what the spring acts upon.

With Series ABVS, this is done by backing off the adjusting cap (so the spring will not be compressed) then unscrewing the spring housing from one side of the actuator and moving it to the opposite side. (Likewise, the compressed air is swapped).

Converting Series ABRS & ABMS is a little more complex. The actuator must be removed from the valve (very easy to do), then a retaining ring on the bottom of the actuator must be removed (requires retaining ring pliers). The pinion shaft is then pushed out from the top, rotated 180º, then re-inserted. The actuator will then act upon the valve opposite the way it did before.

Valves with Programmable Fail-Safe Positions

Some valves have the capability to fail-safe to a variety of options. The CAFE NITRO electric actuator may be used on ball valves and butterfly valves, pre-set to fail-closed, fail-open, fail to a specific degree of open/closed, or fail-freeze as required by the application. The fail-safe position is determined by the user, selected via an on-board menu screen.

Choosing a Default Position

In most applications the default position is determined by the type of valve required. For the two types of pressure control valves shown in the photo above, backpressure/relief valves are generally normally-closed while pressure regulator/pressure reducing valves are generally normally-open. In some cases these default positions have little or no relevance to the application, particularly if either is used for continuous pressure control. In others, such as when a backpressure valve is used in chemical dosing to prevent siphon, default position is of foremost importance.

Default position tends to be more critical in on/off or modulated flow applications. For example, on a filling line or fertilization system where overflow could be a problem, it might be essential to specify “normally-closed.” On the other hand, a process cooling application may need to default to “normally-open” to prevent overheating. These can become dangerous or exceedingly costly if default position is overlooked in processes featuring aggressive chemicals. If you have any questions concerning the most appropriate design for an unusual application, contact our technical group for assistance.

Source: Plast-O-Matic Valves, Inc.