Editorial: How to Avoid This Vital Problem With Pumps

Image source: Crest Pumps Ltd.

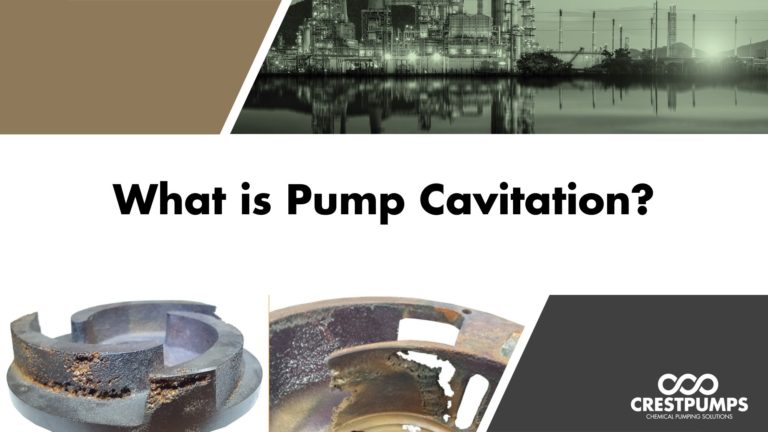

How is it obvious that the pump has cavitated?

If the pump sounds like it is pumping marbles, there is likely a cavitation problem (or marbles have entered your system). Other problems associated with cavitation include excessive vibration that leads to premature seal and bearing failure, higher power consumption, and lower flow and pressure.

Intake cavitation

Occurs when a pump is under low pressure or high vacuum. Signs of suction cavitation are found around the eye of the impeller, which has numerous pits; when cavitation is severe, the impeller resembles a sponge.

Possible causes of suction cavitation are:

- Pump running too far to the right of its curve

- Clogged suction line or strainer

- Poor piping design, including excessively long runs

- High inlet velocity of the liquid

- Poor suction conditions

Cavitation at the outlet

Can occur at very high discharge pressures or when the pump is operating at less than 10% of its best efficiency, resulting in more recirculation within the pump and high fluid velocity at the outer edge of the impeller. The obvious sign of pressure cavitation is pitting at the outer edge of the impeller.

Causes of pressure cavitation include:

- The pump is running too far to the left of its characteristic curve.

- Clogged discharge line or filter

- Poor piping design

How can pump cavitation be prevented?

First, the cause of the pressure drop must be determined. In most cases, the problem can be solved as follows:

Simplifying the suction line by removing as many bends and valves as possible:

- Relocating the pump closer to the fluid source

- Cleaning the piping and removing blockages

- Increasing the diameter of the suction line and thus reducing the inlet velocity.

- Cavitation is a common problem, but impeller damage can be largely avoided if the pump is properly sized, piping is well designed, and filters and strainers are regularly maintained.

Source: Crest Pumps Ltd