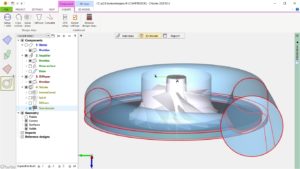

Double Hose-diaphragm Pumps Guarantee Minimum Pulsation and Wear

Long distance hydrotransportation of aggressive or abrasive products is an exceptionally challenging task even for positive displacement pumps. Feluwa’s Multisafe double hose-diaphragms pumps are provided with two hose-diaphragms, which are arranged one inside the other.

Operation example: Three sets of quintuplex pumps for tailings disposal at a mining project in Mexico. (Image: Feluwa)

They ensure linear flow path and redundant, hermetical sealing between wet and drive end.

For high flow rates, by far the highest efficiency and lowest irregularity is achieved by means of single-acting five cylinder pumps. Quintuplex configuration not only allows for uniformities comparable with that of centrifugal pumps, but also contributes to a reduction of valve wear and life cycle costs to an extent that has not been feasible thus far. Even without pulsation dampeners, residual pulsation is reduced to 5.1 % p to p (vs. 23 % of single-acting three cylinder pumps and 32.5 % of single-acting four cylinder pumps).

With slurry pipelines, inevitable variations of the dry solid contents play a decisive role. They not only influence the viscosity of the product, but likewise result in fluctuations of the working pressure. Redundancy of pulsation dampening equipment with Multisafe quintuplex configuration is all the more advantageous as the negating of manually or automatically operated dampening devices is a great benefit as they are usually mandatorily employed when operating at variable discharge pressures.

Source: FELUWA Pumpen GmbH