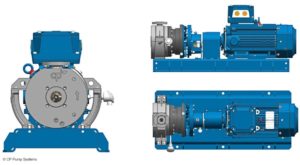

CP Pumpen Highlights Sealless, Magnetically Coupled Centrifugal Pump Made of Solid Plastic

Diffusion-proof and robust: sealless, magnetically coupled centrifugal pump MSKP made of solid plastic (Image source: CP Pumpen AG)

The MSKP is a single-stage centrifugal pump with a wide range of applications and uses. It covers a range from 0.2 to 140 m³/h and a head of 90 m and can be used between -20°C and +150°C.

The pump's housing is made of thick, vacuum-resistant, corrosion- and diffusion-resistant solid polymer. The use of PTFE with carbon filler means that no electrostatic charges are generated on the housing. The MSKP is alternatively available in virginal PTFE or PVDF. The bearing is designed to be very robust and ceramic-compatible and is made of pure SSiC (sintered silicon carbide). This gives the MSKP a high level of operational reliability. Plain and thrust bearings are positively locked and self-centering with polygonal anti-rotation devices.

Despite this high level of quality, the magnetically coupled, seal-less and hermetically sealed MSKP is less expensive to purchase than, for example, some PFA-lined metallic magnetic drive pumps. For this reason, quality- and safety-conscious customers frequently use this design for less demanding media such as sulfuric, nitric, hydrochloric or acetic acid in various concentrations. However, alkaline media such as caustic soda are also frequent media that are pumped.

Special diffusion safety requirements are necessary for bromine, hydrogen bromide, sodium hypochlorite (Javelle) or hydrofluoric acid (HF). Here, the MSKP is characterized by the use of a very thick-walled housing. Furthermore, the selective choice of bearing materials must also be taken into account.

In addition to the large chemical companies, customers from the electronics industry, the contract manufacturing of organic intermediates and also from the sector of explosives production are recurring customers of the MSKP.

Source: CP Pumpen AG