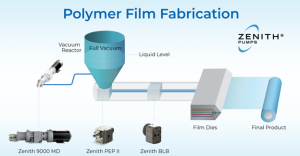

CIRCOR Introduces Precision Gear Pump Metering Systems

CIRCOR Introduces ZENITH 2K Precision Gear Pump Metering Systems (Image source: CIRCOR International, Inc.)

The Zenith 2K systems are engineered to meet the rigorous demands of multi-component applications, delivering unmatched accuracy in metering and mixing processes. These systems offer exceptional accuracy and consistency by using high-precision rotary gears, which provide a smooth, continuous, and pulse-less flow, ensuring impeccable results across applications such as sealants, adhesives, potting compounds, and sealing foams. This level of precision helps manufacturers optimize their production processes, reduce waste, and maintain consistent product quality.

To enhance durability, especially in abrasive applications, the systems feature hardened materials of construction, which prolong the system’s lifespan and significantly reduce maintenance costs. With robust individual components, Zenith’s 2K systems are designed for a long product life, capable of withstanding high wear and tear. Moreover, the systems are designed to provide stable, precise, and repeatable flow control of process fluids, regardless of variations in temperature, viscosity, or pressure.

A seal-less Magdrive option is available, eliminating shaft leakage and mechanical seal failures while providing a leak-free and maintenance-friendly solution. The 2K systems also feature multi-pump capability, allowing for one or more pumps to be driven by a single motor, or more, offering flexibility and efficiency in various production settings.

Zenith 2K Precision Gear Metering Systems are available in various configurations, including the pump Series B, Series 9000, Series 9000MD, and H Series, and can be customized to suit diverse application needs. This customization and flexibility allow users to adapt the systems to their unique production challenges, ensuring reliability and precision at every step.

Source: CIRCOR International, Inc.