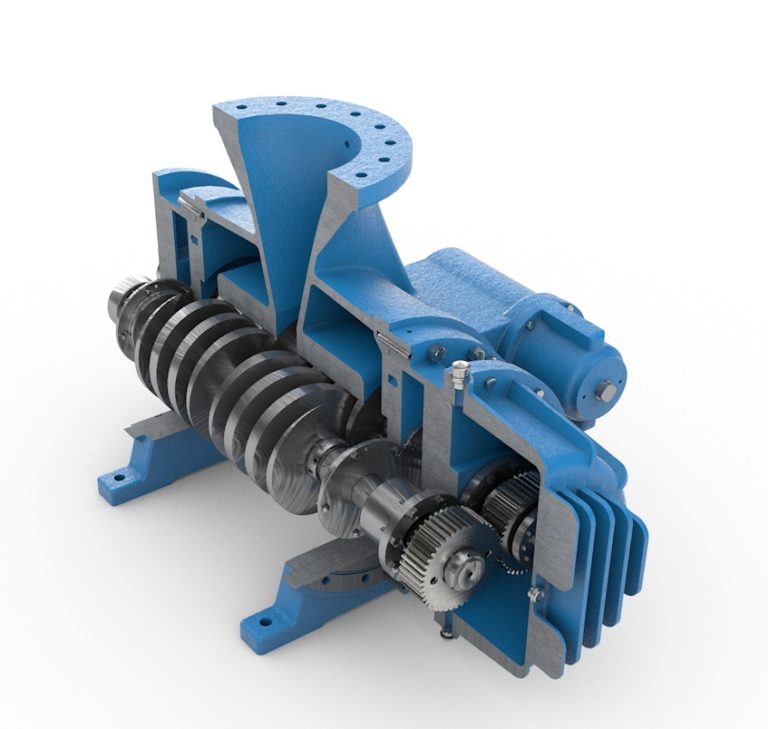

CIRCOR Announces the Houttuin 249.TT Twin Screw Pump

New pump increases speed and flexibility in unloading and transfer applications for fluids. (Image source: CIRCOR International, Inc.)

In combination with the best cost design, it is ideal for oil & gas applications as well as for any process and transport duties in chemical, non-hygienic food and beverage, marine and other segments.

In transfer and unloading applications, the need is speed and flexibility. The Houttuin 249.TT is a non-contacting screw pump, able to pump nearly all types of fluids and fluid mixtures – from light condensate over water to highly viscous chemicals or emulsions. The pump is self-priming, dry run capable, comes with very low NPSH requirements, and is ready to use with the patented CIRCOR cavitation detection solution.

The Houttuin 249.TT’s features and capabilities, including self-priming, resting, handling of various fluids, a wide capacity, and wide pressure and viscosity range, all contribute to its process flexibility for use in changing production requirements.

Houttuin positive displacement pumps offer reliable delivery of a wide variety of fluids at a desired rate, even under changing or unpredictable process conditions. The new 249.TT series offers higher flow capability and lower net positive suction head (NPSH) than similarly sized pumps for unloading and transfer applications. The NPSH optimized integral liner reduces hydraulic inflow losses, allows for a more compact pump, and improves the overall pump efficiency. In combination with the CIRCOR cavitation detector the pump can operate close to the NPSHa limits, unloading tanks faster, independent of the properties of the actual fluid being pumped. The wider speed range allows the use of a smaller pump, saving cost, footprint and energy.

The proven design of the Houttuin 249 twin-screw pump with more than 30 years of successful operation all over the world was the basis for the updated 249.TT pump which features the same reliability with some upgrades to today’s requirements and technologies. “When creating the Houttuin 249.TT, we kept our end users top-of-mind and created a highly reliable, compact designed twin-screw pump offering greater design simplicity and unique features to meet their needs,” said Axel Jäschke, Director Strategic Business Development. “This new member of the Houttuin 200 series, strengthens the benefits that our positive displacement pumps already afford in the process and transport space: the reliable delivery of a wide variety of fluids at a desired rate, even under changing or unpredictable process conditions.”

The integrated, patented CIRCOR cavitation detection, the low NPSH requirement and the modern fabrication methods used in the Houttuin 249.TT provide you with a highly efficient pump that can help you minimize CAPEX and OPEX for your installation.

Source: CIRCOR International, Inc.