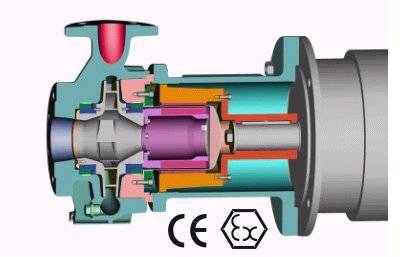

ATEX- certified centrifugal pumps

(Radolfzell) The ALLMAG-Series of the Allweiler AG is specially aimed at the chemical industry. All pumps have been ATEX- certified from the middle of this year. Hence they comply with the EC-Regulations that are demanded from 1.7.2003 on when installed for the first time and for initial operation. The certification applies to the categories 2 and 3 and all temperature classes of the new standard.

ATEX-certified ALLMAG-Series

The certification already ensures the operators and consulting engineers a smooth implementation of Installations that are first under construction. Furthermore a certification for many companies in the chemical industry is today already of great importance. With the early certification the Allweiler AG yet managed in 2002, as the first German manufacturer to come to terms with the BASF AG requirements concerning explosion protected pumps. Stefan Werner, Product manager of the Allweiler AG: „Important for the award of contract was that we had already affiliated the internal certification and could therefore guarantee the complete certification by the end of 2002.“ The Allweiler AG does more than comply with the conformities of the manufacturers. External and officially ordered inspection authorities additionally confirm the standards.

The EC-Regulation „94/9/EG“ also includes for the first time non-electrical parts of the aggregate. For pumps, an explosion protected motor can no longer satisfy regulations. While under operation in an explosive area all mechanical parts must also be secured against ignition. Under operation and in case of disturbance, for example due to wear, the aggregates must not reach the surrounding ignition temperature. The magnetically coupled volute centrifugal pumps of the ALMAG-series satisfy the standard requirements in all four temperature- classes, that means they allow conveying fluids up to a maximum temperature of 350 OC. This accepts categories „2“ and „3“ of the standard, so operation in explosive surroundings of frequent and short period.

All the pumps of the manufacturer now certified, satisfy the inspection requests without having to make changes to the construction. The Series has formerly been running under explosive conditions without disturbance. Merely the category “2” (“frequently explosive”) is included in the Standard, applied by installing a motor load monitor to quickly recognise cases of dry running, overload and operation with closed pressure- or suction slide.

Basis of the certification are test and measuring runs that are performed well over a years period by the manufacturer. The hazard analysis enfolds the examination of ignition critical sources especially disturbances as the failing of the cooling system and/or flow of conveyance fluids as well as bearing damage. Basis for the evaluation was a hazard analysis complying with DIN EN 13463-1. This covers numerous temperature measurements on different parts and the listing of possible dangers with the methods to minimize them. Michael Leutner, developing engineer at the Allweiler AG: „Future ATEX-certifications can be done in a few weeks due to this acquired know how.“ Depend-ing on market demands, other series can be ATEX-certified on the short. This is important, because the manufacturer is expecting the Standardisation to expand to other industrial sections as well as to countries outside the EU.

The ATEX-certified ALLMAG-Series includes aggregates with conveyance flows up to 80 m3/h, conveyance heights up to 55 m, media temperatures up to 350 OC and nominal pressures up to 16 bar. All aggregates are hermetically sealed due to magnetic couplings. They are ideal for toxic, volatile and other dangerous fluids.

About Allweiler AG

Allweiler AG is the oldest German pump manufacturer (founded 1860) and European leader on the market and in technology with centrifugal-, propeller-, screw-, eccentric spiral pumps, and macerators as well as peristaltic pumps. Allweiler AG owns its own foundry and constructs ready for use fuel installations. Since 1998 Allweiler AG is part of the Colfax Pump Group, that is the worldwide leader in the manufacturing of pumps. With 1150 employees Allweiler AG reached in 2001 a turnover of 126,2 Mio. EUR (previous year 117,5 MEUR). 2002 135 Mio. EUR are planed.

Source: ALLWEILER GmbH