Amarinth Delivers Titanium Pumps for FPSO Vessels in Brazil

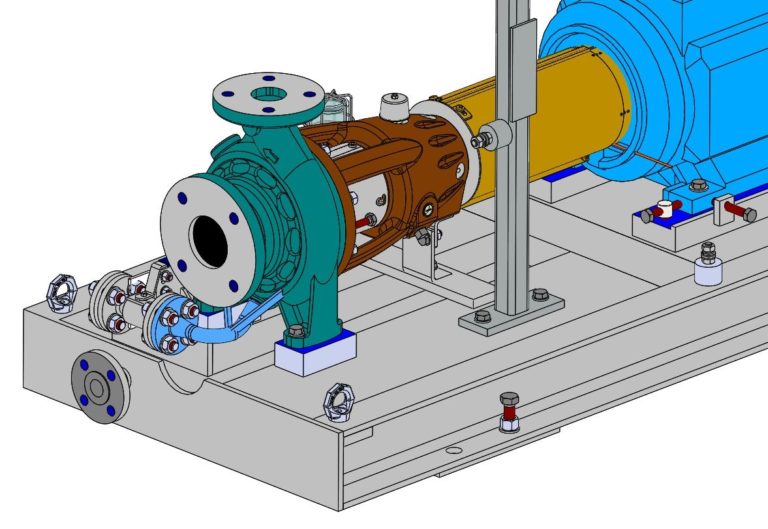

3D CAD model of an Amarinth titanium pump being designed for VWS Westgarth to be installed aboard an FPSO vessel. (Image source: Amarinth)

The order of four pumps from VWS Westgarth, the largest single supplier and operator of sulphate reduction membrane systems, was for chemically enhanced backwash pumps to be installed aboard two Floating Production Storage and Offloading (FPSO) vessels operated by Petrobas off the coast of Brazil.

The pumps are ATEX certified for hazardous areas and incorporate auto start stop modules for unattended operation. To handle the highly corrosive fluid, all wetted parts of the pumps are manufactured in titanium, including the casings, impellers and shafts. Titanium is a difficult material to work with and must be cast under a full vacuum using copper crucibles to prevent the molten titanium attacking the crucible walls. The UK has one of only a few foundries in the world with the capability to cast large titanium components. Amarinth worked closely with this UK foundry to ensure an optimum design for the castings to maintain the correct flow of the molten titanium over changes of dimensions and directions.

Furthermore, Amarinth had to deliver the pumps to a tight 28-week deadline amidst the Covid-19 pandemic. Amarinth saw the scale and potential impact of the Covid-19 pandemic early in the outbreak and quickly leveraged its engineering and commercial agility and investment in remote working technologies to make the necessary changes to its business model, ensuring the company could work with its customers and suppliers to maintain critical on time delivery of pump orders.

Despite the engineering challenges, compounded by the Covid-19 pandemic, Amarinth’s strong relationship with its supply chain, and the Covid secure working practices it put in place, enabled the company to design, manufacture and deliver the pumps to meet the 28-week deadline for the project.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “We are delighted to be supplying these pumps to VWS Westgarth. This order once again underlines our expertise in providing high-quality reliable pumps designed to meet the arduous conditions aboard FPSO vessels, along with our world leading capability in designing and manufacturing titanium pumps. With the changes we made to our business model early in the Covid-19 pandemic, we have been able to maintain our enviable on-time delivery record, not only for this order but to all of our customers over this past year.”

Source: Amarinth Ltd.