Air-Operated Double-Diaphragm Pumps Are Designed for Maximum Performance and Reliability

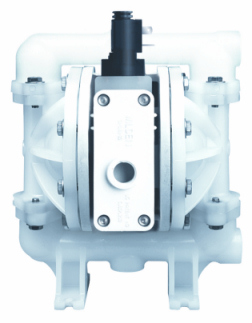

Wilden has designed its Advanced Plastic Series A100P Air-Operated Double-Diaphragm Pumps to deliver the highest level of performance and efficiency while meeting the required abrasion, temperature and chemical-compatibility parameters.

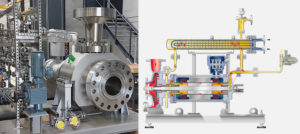

Wilden Advanced Plastic Series A100P Air-Operated Double-Diaphragm Pumps (Photo: Wilden)

The A100P is a 13mm (1/2”) pump that features a bolted configuration that ensures total product containment. Additionally, its redesigned liquid path reduces internal friction to maximize output and efficiency. The pump delivers flow rates up to 42.4 lpm (11.2 gpm) with a maximum pressure of 8.6 bar (125 psi). It has a maximum dry-suction lift capability of 6.6mm (21.5”) and can handle solids with a diameter of 1.6mm (0.06”). Elastomer options include Buna-N, polyurethane, Saniflex, PTFE, Viton and Wil-Flex.

The operation of the A100P pumps is maximized through the use of Accu-Flo technology. This technology employs a two-position, four-way solenoid valve that has a single operator and spring return, allowing the valve to be internally air-piloted for longer coil and operator life. Air pressure is utilized to fill air chambers and displace the diaphragms with electrical impulses dictating the stroke rate. By alternately applying and removing electrical power, the Accu-Flo pump reciprocates back and forth similar to standard air-operated pumps, leading to increased pump efficiency.

Source: Wilden