Abel Pumps in Corrugated Cardboard

Today, corrugated cardboard packaging is seen everywhere. However, even though this product has been around for over 100 years, few know how complex the production process is and how varied the product is depending on configuration and structure.

Electromechanical diaphragm pump, Type EM-040Z0300-SG for

glue circulation (Image: Abel Pumps)

Klingele Papierwerke has been producing raw paper for corrugated cardboard in two different locations, in France and in Germany, for more than 50 years. These raw papers are the basis for producing packaging and corrugated cardboard products.

In their factory in Werne, Klingele produces corrugated boxes, die-cut packaging and folding boxes in various shapes and sizes.

Corrugated cardboard is light and at the same time stable. Its secret – as the name indicates – are the corrugations that lend the cardboard very high stability. At the same time, the air-filled chambers created by the corrugations ensure its unique cushioning function. The product is produced by combining different layers of paper by means of starch glue. Fluted sheets and flat liner boards are glued to each other in several layers, so that the final result is a single, dual, or triple wall corrugated cardboard.

The core manufacturing piece is the flute lamination machine. This very long machine consists of several individual units which are separately and independently controlled.

Inside, the individual layers of paper are heated, moistened, laminated and then dried. Afterwards the desired format is cut to size.

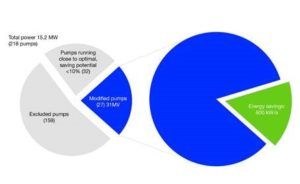

An important component in manufacturing corrugated cardboard is the glue that is used. Klingele uses glue that is based on natural starch. Electric diaphragm pumps made by Abel are used to transport the glue at a temperature of 35 – 40°C to and from the flute lamination machine as well as for continuous circulation. These pumps are electrically driven, dual effective diaphragm pumps with mechanical membrane deflection. Unlike the previously used compressed air diaphragm pumps, they generate considerably less noise; the irritating ventilating noise when the control valve is triggered does not occur. In addition, the energy balance is impressive. The Abel EM pumps offer high efficiency and consume far less energy than pumps operated with compressed air. Cost savings are especially significant during continuous operation.

Energy conservation was one of the main reasons Klingele selected these pumps. All installed pumps are frequency-regulated. Being true positive displacement pumps, EM pumps are very tolerant of changing degrees of viscosity of the pumped glue and therefore can deliver constant and consistent flow independent of counterpressure.

The first Abel EM pump was delivered and commissioned in the summer of 2011. Since then, another 7 identical EM pumps have been added. All of the glue pumps in the corrugated cardboard factory in Werne have been completely switched from compressed air drive to electric drive. The EM pumps provide reliability, efficiency and low operating costs to our customer. That’s the Abel difference.

Source: ABEL GmbH