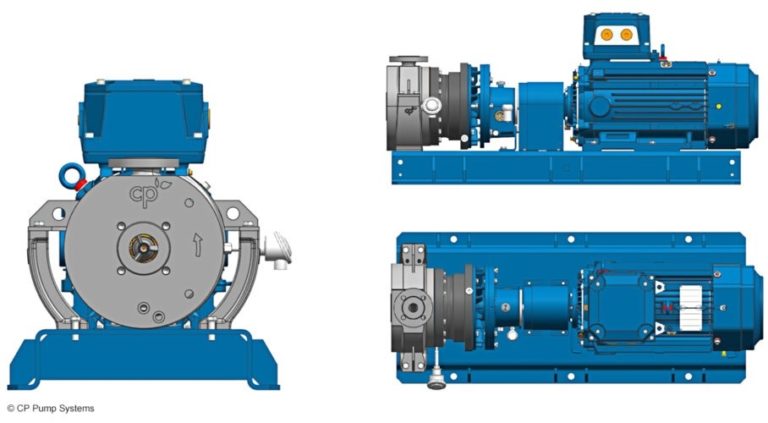

CP Pump Systems: The New MKP Montage “OH2 HT”

The new MKP montage "OH2 HT". (Image source: CP Pumpen AG)

Due to the centre-braced pump casing, the natural thermal expansion of the pump casing in high temperature applications is compensated in the best possible way. The slightly off-centre location of the feet on the pump casing chosen by CP takes into account the thermal expansion of the lateral feet themselves and thus keeps the position of the central axis of the pump absolutely stable, irrespective of the pump temperature. The chosen swept shape of the feet reduces stress peaks and notch effects on all components even when pipeline forces act.

The built-in thermal barrage effectively decouples the bearing frame from the pump, so that commercially available bearings and lubricants can be used here.

The pumps can be used up to 350 °C and are available in PN16 and PN25 versions.

The inset closed yokes offer all common MKP safety options, such as temperature monitoring of containment shell, secondary containment, a yoke connection for leakage monitoring and a yoke connection for pressure monitoring, and thus ensure maximum safety.

The design of the magnetic drive montage variant "OH2 HT" can be equipped with a heatable casing if the customer so desires. The CP heating casing is specially manufactured for optimal heating and heats up with the aid of a single heating chamber. This ensures excellent heat distribution in the pump, reducing temperature differences and avoiding cold zones. In addition to a high heat transfer coefficient and the direct supply of heating energy into the fluid chamber, the heating times are shortened and energy costs are saved as a result.

The pumps are available in 26 sizes and cover delivery heads of up to 230 m with flow rates of up to 1300 m3/h.

Source: CP Pumpen AG