Reliable Pump Solutions for Flammable and Combustible Liquid Transfer

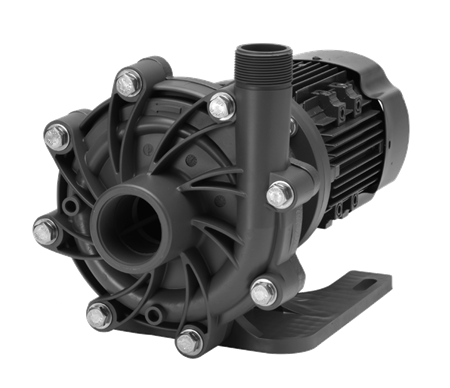

Centrifugal and mag-drive technologies deliver safe, compliant performance for hazardous fluid handling (Image source: Finish Thompson Inc.)

Engineered for critical containment and operator safety, FTI’s centrifugal pump portfolio includes a wide range of sealless mag-drive designs capable of transferring a wide spectrum of flammable, combustible, and corrosive liquids. Selecting proper materials of construction is essential when managing hazardous substances, and FTI provides expert guidance to ensure pump components are compatible with the liquid’s specific properties, concentration, and temperature. For highly aggressive materials and flammable applications, options such as high-purity fluoropolymers, advanced alloys, and specialized elastomers are available to offer robust chemical resistance and operational reliability.

Safety and regulatory compliance are paramount when handling flammable liquids. The National Fire Protection Association’s code for flammable liquids recognizes the need for pumps with explosion-proof motors and groundable components, and FTI incorporates these design requirements into its product offerings for hazardous environments.

Unlike conventional sealed pumps that can leak due to seal failure, FTI’s DB series, MSDB series, and UCR series of mag-drive centrifugal pumps eliminate the mechanical seal entirely. Power is transmitted to the impeller through a magnetic coupling and a corrosion-resistant barrier, vastly reducing the risk of leaks and emissions of hazardous substances. Mag-drive pumps also help minimize downtime and maintenance costs while supporting safe dry-running operation depending on the design and material.

Similarly, FTI’s EF series drum pumps provide explosion protection, while sealless construction helps prevent leaks in hazardous environments. With interchangeable power options and chemical-resistant materials, the EF series supports reliable, compliant transfer of flammables. The upcoming SX series explosion-proof motor (available November 2025) expands these capabilities with a lightweight, two-speed design, enabling both rapid drum emptying and controlled filling of smaller containers, while advanced grounding features further enhance safety during the transfer of flammable and combustible liquids.

Source: Finish Thompson Inc.