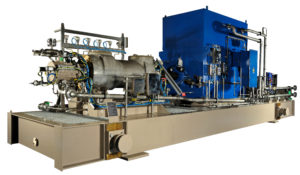

Quick Opening Closures from Celeros Flow Technology Support Safe and Cost-Efficient Operation

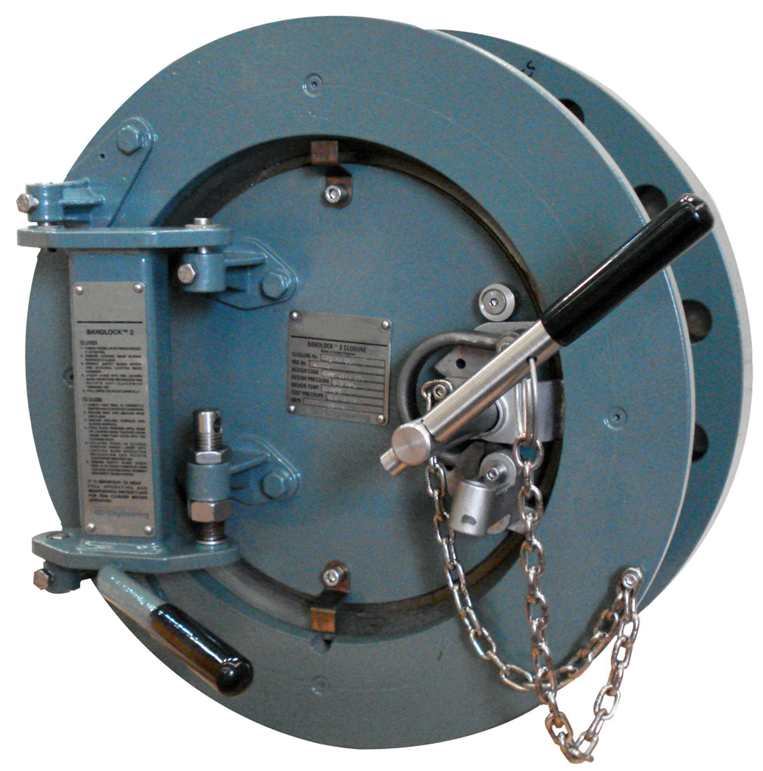

GD Bandlock2 Quick Opening Closures from Celeros Flow Technology are designed to prevent downtime and safety risks caused by premature failure. (Celeros Flow Technology)

GD Bandlock 2 Closures provide horizontal or vertical access to any pressure vessel and can be operated safely at remarkable speed. They feature a unique locking band technology that ensures the closure cannot be operated if any residual pressure remains in the vessel or pipeline. This mechanism will function reliably regardless of pressure vessel size or operating conditions.

Without compromising on safety, GD Bandlock 2 quick opening closures are also designed for efficient access. They support "one man one minute” operation without the need for any special tools, which significantly reduces the cost of operations. In combination with the tried and tested locking mechanism, this quick access design means that customers can uphold the highest safety standards without compromising on operational efficiency.

Bandlock 2 closures are manufactured in the UK by Celeros Flow Technology brand GD Engineering, who are experts in advanced pipeline access and pigging solutions. These innovative access solutions are complemented by full lifecycle support, including seal refurbishment / replacement, and expert technical advice on how to maximize performance.

Source: Celeros Flow Technology