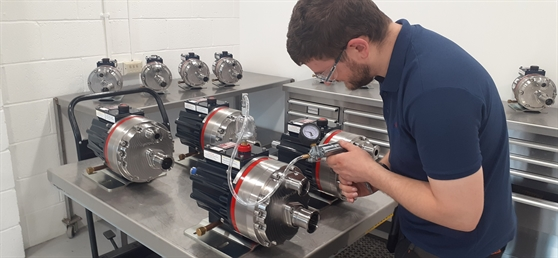

WANNER Hydra-Cell Pumps Ensure Process Reliability in the Pharmaceutical Industry

WANNER Hydra-Cell Pumps Ensure Process Reliability in the Pharmaceutical Industry (Image source: Dynapumps)

Process Reliability, Accuracy and Consistency

- Reliably handles non-lubricating, abrasives, corrosives, and liquids with micron-sized particles

- Extremely low pulse flow; no pulsation dampeners needed in most applications

- Ultimate steady-state accuracy and controllability

- Exceptionally wide adjustable flow range

- Compact design, saving on installation space

- Low shear pumping action

Seal-less design (the pump has no dynamic seals in contact with the process liquid) means that non-lubricating solvents and liquids containing suspended particles can be pumped reliably at pressure in HPLC (High Performance Liquid Chromatography), ultrafiltration, nanofiltration, reverse osmosis and ultra-high pressure reverse osmosis systems.

Pilot plants used in process development and production installations for handling the waste stream are typical applications.

- ANSI, DIN, Tri-Clamp, ASME BPE flange connections

- Process contact surfaces polishing to 0.8 Ra or less

- Diaphragm options to FDA compliance

- ATEX certification

- TSE/BSE-free materials

- Full material traceability

Applications

- Flow Chemistry

- High Performance Liquid Chromatography (HPLC)

- Low Pressure Liquid Chromatography (LPLC)

- Transfer, Blending & Injection

- Coating

- Spray Drying

- Clean in Place (CIP)

Dynapumps can help you with our extensive knowledge in pharmaceutical applications and Hydra-Cell product range.

Source: Dynapumps