Sulzer Pumps Launches New Pump Performance Expert Service

Sulzer Pumps has launched a new Pump Performance Expert service for customers in the pulp and paper industry. This new global service will contribute not only to reducing customers’ Total Cost of Ownership (TCO) but also to achieving significant benefits in their existing and future processes.

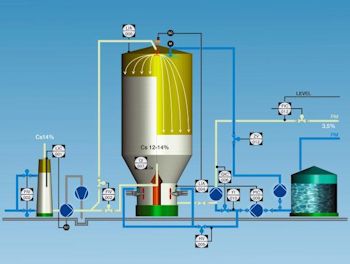

Sulzer Pumps’ extensive product and applications knowhow contributes to the improvement of customers’ processes (Image: Sulzer)

The Pump Performance Expert Service focuses on MC (medium consistency) applications, agitation and mixing applications, tower channeling and discharge. This service is applicable for both the installed bases of Sulzer Pumps and other Original Equipment Manufacturers (OEM). By applying our in-depth knowhow and expertise in diagnostics and regular mill surveys our customers can achieve extensive performance improvements in mixing, agitation and pumping applications.

Through this service, customers will significantly benefit from simplified applications, energy savings and more flexible processes with reduced chemical consumption, operation costs, maintenance and process down time. Customers will gain from a wide range of savings in pumping, mixing, agitation and tower management applications, all in one package. Additionally to this service, Sulzer Pumps offers large mill and corporate wide agreements to further reduce TCO.