Sulzer and Wetend Technologies Launch new Hygienic Injection Pump Series as a Result of Joint Development Project

Sulzer and Wetend Technologies are launching an innovative hygienic injection pump series (SHS) with several patent-pending features. The SHS pump series will meet the current and future standards of process reliability and improve the performance of demanding injection applications.

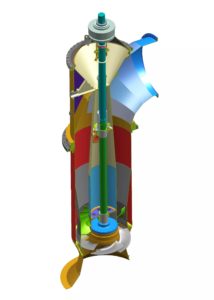

New Hygienic Injection Pump Series (Image: Sulzer)

For our customers the new pump design provides the highest standard of hygiene and cleanliness. The compact and light pump design improves operational efficiency and sustainability of the injection process.

The technology of the new hygienic injection pump is based on a joint development project with Wetend Technologies – a global leader in injection flash mixing technology (TrumpJet Flash Mixing systems), Randax – a developer of modern drive solutions with integrable permanent magnet motors, and John Crane – a world-leading provider of engineered products and services. Wetend is the primary sales organization of the new injection pump, which is an integral part of the TrumpJet system.

The new pump series with unique design features has been developed by Sulzer for demanding injection applications especially in the pulp and paper industry. It is also suitable for the general industry, chemical process industry, power generation, water and wastewater, oil and gas, and hydrocarbon processing industries. The pump is designed especially for fibrous slurries with high internal cleanliness, but can also be used for a wide range of other liquids, including clean and slightly contaminated liquids, viscous liquids and non-fibrous slurries.

The pump has a hygienic, smooth and low-pulse wet end design. The heavy-duty patentpending case divides the flow into as many as seven equal flows, eliminating the conventional piping arrangement. The pump comprises a patent-pending open impeller, an integrated single or double mechanical seal and a compact bearing unit that minimizes axial and radial play as well as shaft deflection.

The patented high-efficiency permanent magnet motor developed by Randax enables the most integrated and compact pump design. The lightweight but powerful Randax motor is optimized for the hygienic injection process pump and is ready-to-use for fast commissioning. The durable motor is designed for inverter use and is maintenance-free due to its integrated design, which makes the whole pump unit easy and quick to install.

The new injection pump is an integral part of the Chemical Reactor development of Wetend for paper and board mill additives. The TrumpJet Flash Mixing Reactor is a novel compact design for efficiently injecting several chemicals with a controlled and fast chaos pattern of mixing, located very close to the paper or board machine head box. It cuts down the consumption of chemicals, can increase the paper filler content, improves formation and opens an opportunity to develop composite-type paper and board structures.

The innovative design of the new hygienic injection pump series keeps the system clean and minimizes the total life cycle cost by reducing energy, installation, operation, maintenance, downtime, and environmental costs. This true cleantech solution further supports the sustainability targets within the industries we serve.