Smart End Position Monitoring for Manually Operated Valves

Auma offers a new sensor system for signalling valve end positions which can be mounted to the company’s GS .3 part-turn gearboxes. The new solution allows plant operators to monitor the position of manually operated valves, and hence to collect crucial valve position information from all the valves in their plants – not just from motor-operated valves, which mostly use the integral limit switching functionalities of the actuators.

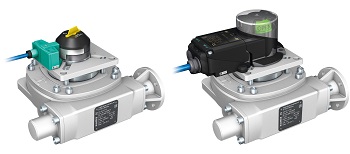

The basic version (left) and the premium version (right) of Auma’s new end-position sensor system for GS .3 part-turn gearboxes. (Image: AUMA)

The new sensor system adds intelligence to valves at a time when collecting and processing data from smart field devices is at the core of a rising number of Industrial Internet of Things (IIoT) applications in process automation.

The sensor system can also be used in combination with electric valve actuators when redundant valve end position feedback is required in addition to the actuator-embedded functionality.

The new sensor system uses inductive sensor elements which ensure contactless monitoring of the end position for 90° part-turn valves. In contrast to mechanical limit switches, the electronic sensor system is wear-free and not subject to corrosion. It combines high switching accuracy with robustness.

GS .3 gearboxes can be ordered with the integral sensor system as of now. Thanks to its modular design, the sensor system can also be easily retrofitted to existing GS .3 gearboxes in the field. The sensor system is available in two versions: a cost-efficient basic version and a fully-sealed premium version with aluminium housing offering enhanced IP69K protection. The premium version is particularly suitable for outdoor installation. Both versions are also available with ATEX approval for use in potentially explosive atmospheres.

Source: AUMA Riester GmbH & Co. KG