Rotamec and JPS Reliability combine to boost plant uptime

JPS’ reliability technologies will dovetail with Rotamec’s electromechanical maintenance resource, with customers able to benefit from the expertise of both organisations in a combined service.

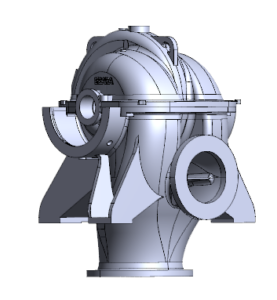

An expert in rotating equipment, Rotamec is a leading UK service provider to the food and beverage, facilities management, utilities and manufacturing sectors. The business specialises in the repair and sourcing of motors, gearboxes, pumps, generators and associated power transmission equipment. Providing a 24/7, 365 days-a-year maintenance service - supported by highly responsive on-site teams, machining and repair facilities across the UK – Rotamec’s customers have the support required to secure equipment uptime.

JPS Reliability provides a professional service to enable proactive maintenance with over 40 years’ experience in this specialised field. Utilising vibration analysis, thermal imaging and ultrasound – the business offers comprehensive condition monitoring for an array of equipment. Additionally, a maintenance engineering capability incorporating planning, management, mechanical repairs, lubrication, dynamic balancing and laser alignment ensures that maintenance work is streamlined and asset reliability enhanced.

Simon Brooks, Managing Director at Rotamec, said: “Our new association with JPS Reliability will allow Rotamec customers to further improve equipment reliability. The on-site condition monitoring and maintenance services provided by JPS Reliability will seamlessly integrate with our rotating equipment expertise, including in-house repair and sourcing capabilities. We are excited to begin this new combined service.”

Amanda Graves, Business Development Director at JPS Reliability, added: “Both Rotamec and JPS Reliability share a desire to enhance the reliability of customer equipment. Our specialist reliability services are designed to boost plant uptime, so our new association with Rotamec will mean combining and developing our services to maximise this benefit.”

Source: Rotamec Ltd