Pump Selection With LCC Calculation

VSX – VOGEL SOFTWARE updated Spaix V2 and expanded its functions by adding the calculation of Life Cycle Costs (LCC), the analysis of parallel pump circuits and the integration of on-line news as well as improved update functions.

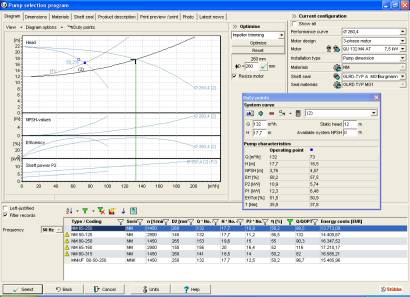

Parallel pump sizing with Spaix V2

Calculation of Life Cycle Costs

Not only the purchase price but the total costs are gaining importance when purchasing technical units. Thanks to a common initiative by the largest manufacturer organizations Europump and Hydraulic Institute, this subject has been more and more sensitized throughout the pump industry.

The Spaix developers – besides technical aspects - attached great importance to the economical side of the pump selection. The automatic price and energy cost calculations for example, reflect these efforts. This update extends the energy cost calculation by a complete Life Cycle Cost calculation. It is up to the user to decide whether to apply the methods of the Hydraulic Institute and Europump or the ones according to VDI 2067.

Configuration of Pumps in Parallel Circuits

The selection of pumps is normally done, such that efficiency, power intake and cavitation properties are optimised with regard to the nominal duty point. In reality, however, it is often the case that the system is run either in serial circuit or in parallel circuit with only a few pumps that are available to the system. For certain applications this so-called partial load operation can even constitute the largest portion of the entire operating time. That is why the single pump operation should – besides the system as a whole – be considered.

For a selection of multiple pumps in parallel circuits, Spaix V2 checks the validity of the duty point for single operations with regard to the application, the power intake and the NPSH value. The user will be reminded of possible incorrect selections and can avoid them by changing the configuration. In combination with the friction loss calculation module Spaix PipeCalc it is even possible to do an exact calculation of multiple pipe curves.

Online Integration

Spaix V2 continues to follow the trend of integrating on-line and off-line applications. This way, the advantages of both options are used. The advantage of on-line solutions i.e. Internet-based applications, is the centralized data update. The off-line application (Windows program), on the other hand, does not depend on a constant Internet connection and avoids the transport and saving of internal company data on the web. It can use the functions of the Windows platform directly - without any interpreter or virtual machine.

The advantages of both technologies are found in Spaix V2. The automatic update function allows an easy allocation of data updates through the internet. If the software is also distributed to customers, pump manufacturers can avoid the costly CD production at every update. Furthermore, the integrated on-line news provide the latest news for the respective user.

The program update to version 2.1 can also be installed through the integrated update function. It is free of charge to all Spaix V2 users.

A free demo CD can be requested on the VSX – VOGEL SOFTWARE website.

About VSX - VOGEL SOFTWARE

VSX – VOGEL SOFTWARE is one of the world’s leading suppliers of pump selection software. With its product line Spaix®, pump manufacturers will find a complete collection of pump selection software, web applications and data administration tools to cover multiple tasks with only one database.

Besides the software itself, the company offers a wide range of services, e.g. data input, interface programming, free phone and e-mail hotline, CD duplication and web services. With the pump search engine and the pump industry news, VSX publishes global pump related web sites with varied free services.

The references contain the world’s largest pump producers, such as ITT Industries, EBARA, KSB, ABS and Wilo-Salmson, just to name a few.

Source: VSX – VOGEL SOFTWARE GmbH